The beginnings of Turbochargers spans back to 1885-96 when Rudolf Diesel and Gottlieb Daimler began investigating ways to improve the internal combustion engine. Their main mission was to minimize fuel consumption but with increased output efficiency. That was when the idea of combustion and pre-compression of air was first mooted.

Since then, the turbocharged engine has gone through continuous refinement leading up to the present-day role they play in giving every car that extra spark of performance by feeding its engine with more air. This article attempts to highlight some facts about gearheads' favorite performance mod that may not be obvious to everyone, including some turbofans out there.

14 First Turbo Application After Alfred Büchi

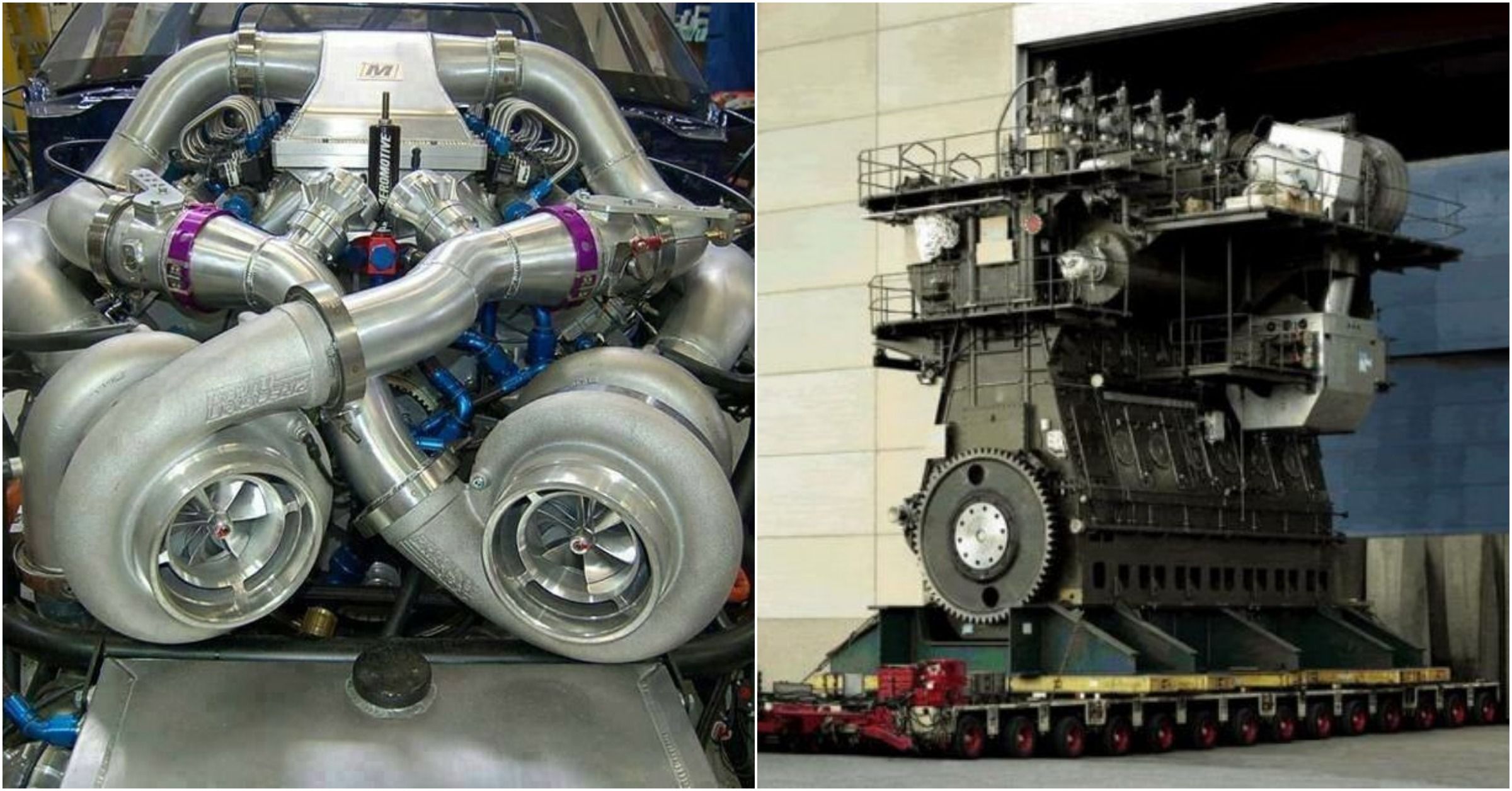

The use of turbochargers in the early days of their invention was in the shipping industry back in 1923. Around this time, turbo engines were implemented on diesel engines (four-stroke) types. Marine engines were able to upgrade a vessel’s power capability from 1,750 hp to 2,500 hp. In 1952, Dorthe Maersk became the first commercial ship to be propelled by an 8,000-hp turbo engine.

13 First Turbo-Driven Oldsmobile of 1962

Oldsmobile Jetfire and Chevy Corvette Monza car models of 1962 were the first to test out the power of turbo engines. Although these cars were short-lived, the trials spurred an increased interest in the development of turbo-driven car engines. It was not until 1978 that Mercedes-Benz produced the first turbo-driven passenger car - the Mercedes Benz 300 SD with a turbocharged 5-cylinder W116 engine.

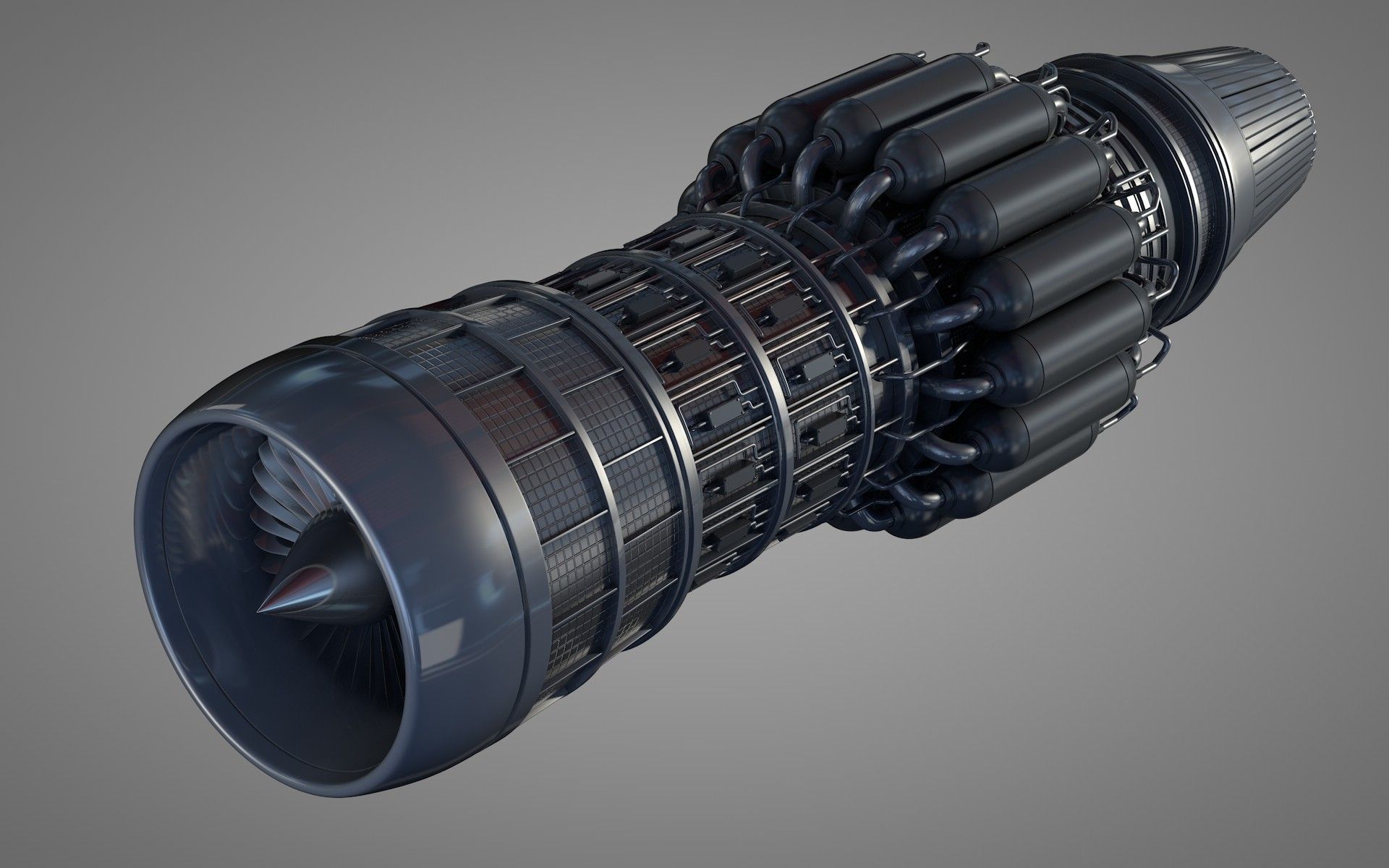

12 The World's Largest Turbo (107,389 hp)

The world's most powerful turbo engine and the largest is in the ocean-conquering container ship Emma Maersk. The Finnish-made turbo powered diesel engine is a 14-cylinder powerhouse, built to unleash a jaw-dropping 107,389 horsepower. And to crown it further, the ocean liner receives 7 million Newton meter of torque from it (about 5,16 million lb-ft). Fun facts: the engine is about as tall as a two-story building; it can crash a military tank into minced shreds, and it’s capable of supplying power to an entire city.

11 Disadvantages of Too High or Too Low Turbo Boost

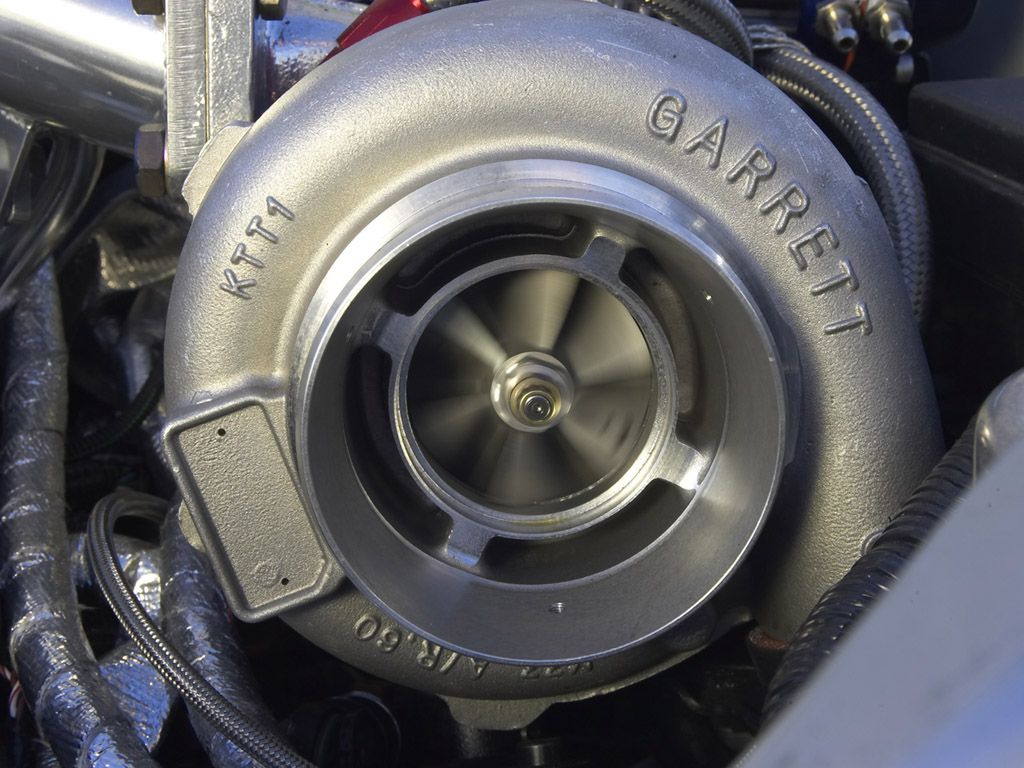

The Turbo engine is sectioned into two parts: the housing bracket and the turbine wheel. As the housing directs gas from the exhaust to the wheel of the turbo, the resultant energy spins the turbine wheel. So more compressed gas means more boost, yet too much of it can damage the engine. On the other hand, a low boost can arise due to a leaky gasket, thereby reducing pressure and so turbo won’t produce power.

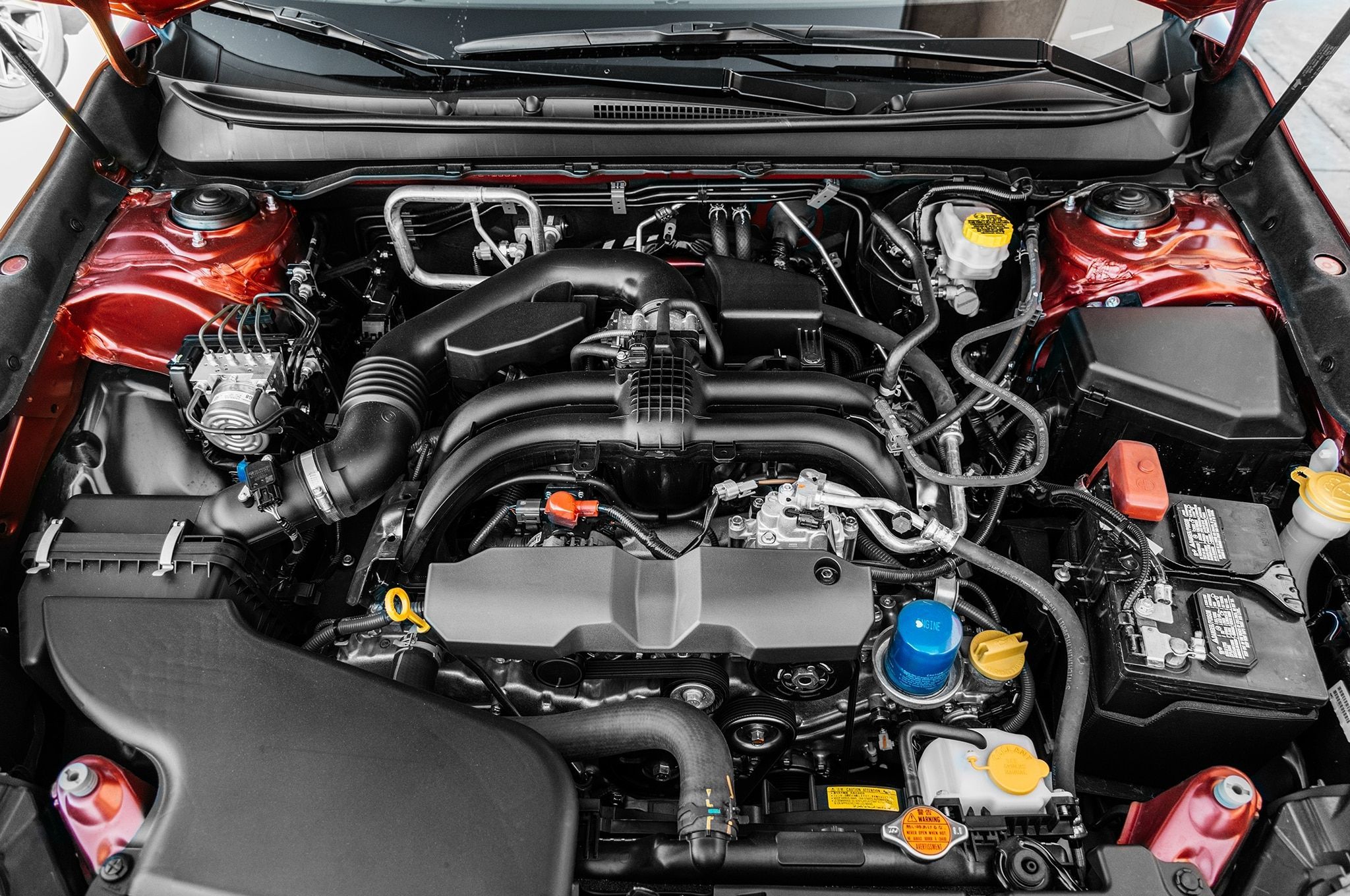

10 Turbo’s Mean Time To Failure

With little modifications, a turbo engine can be installed in any conventional gasoline car. Such modifications often result in a power increase in the region of 50 horsepower. Turbochargers typically begin to show signs of trouble when mileage clocks around 100,000 to 150,000 miles. However, regular maintenance can extend the length of your turbocharger greatly.

9 It Spins At Insane RPMs

Whereas your average everyday car will be able to rev up to 7,000 RPM, A turbocharger can spin up to 150,000 RPM. That's more than 20 times faster, which is why the sound is so audible and unique.

8 Advantages of The Variable Geometry Turbo Charger (VGT)

The Variable geometry turbocharger (VGT) was designed differently from the fixed type to achieve three objectives: ( 1) To attain the highest engine torque, (2) To create seamless turbo response time, and (3) To boost air intake during low engine speeds. This topology was used in the Mercedes Benz 300 SD that became the first passenger car to attain near-petrol drivability with a turbocharged diesel engine.

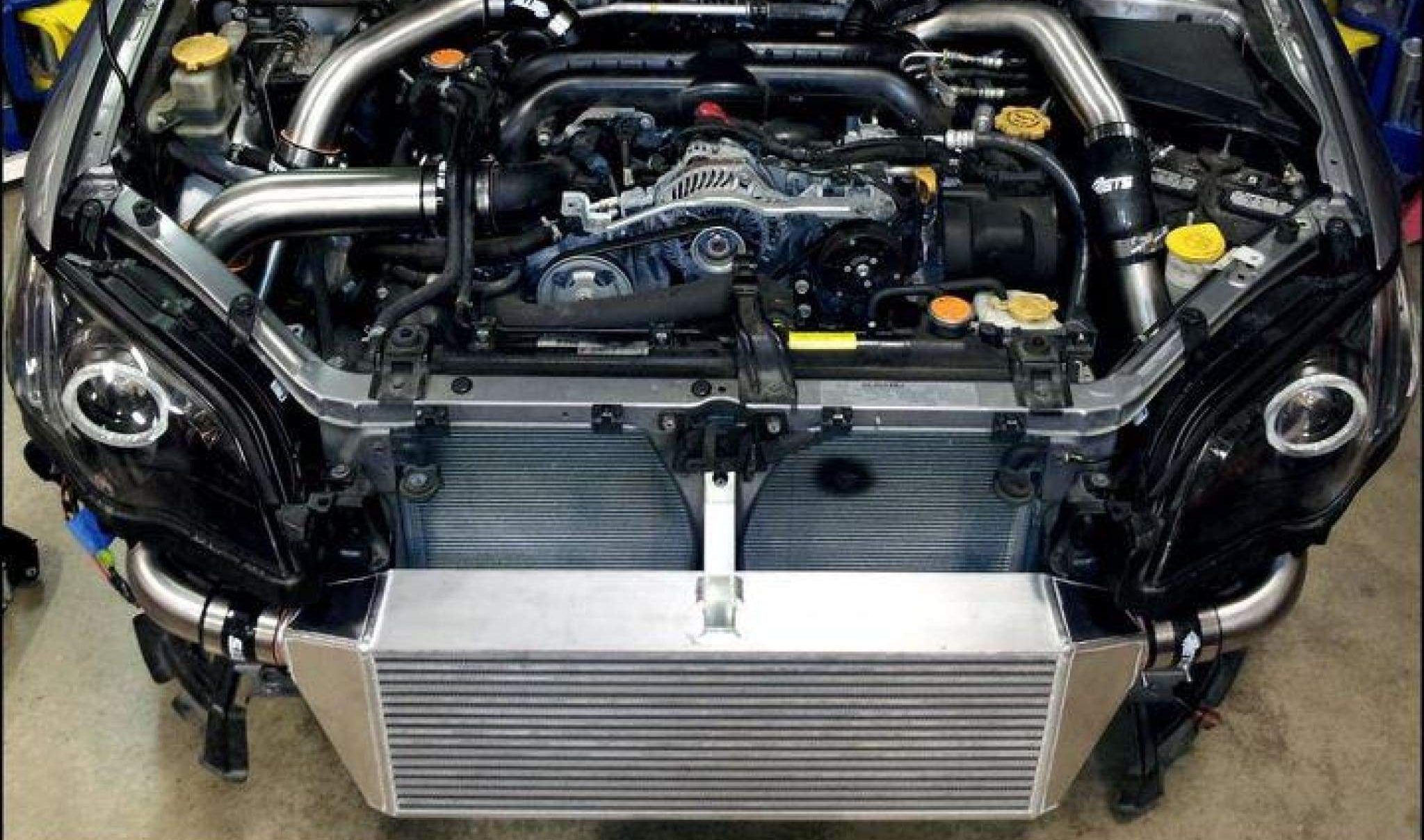

7 The Purpose Of The Intercooler

While more air getting sucked into the turbocharger usually means more power to the engine, we don't want that air to be hot (thus expanding). Therefore, a device called the intercooler is used. It cools the air entering the turbo down to shrink it, providing even more bang.

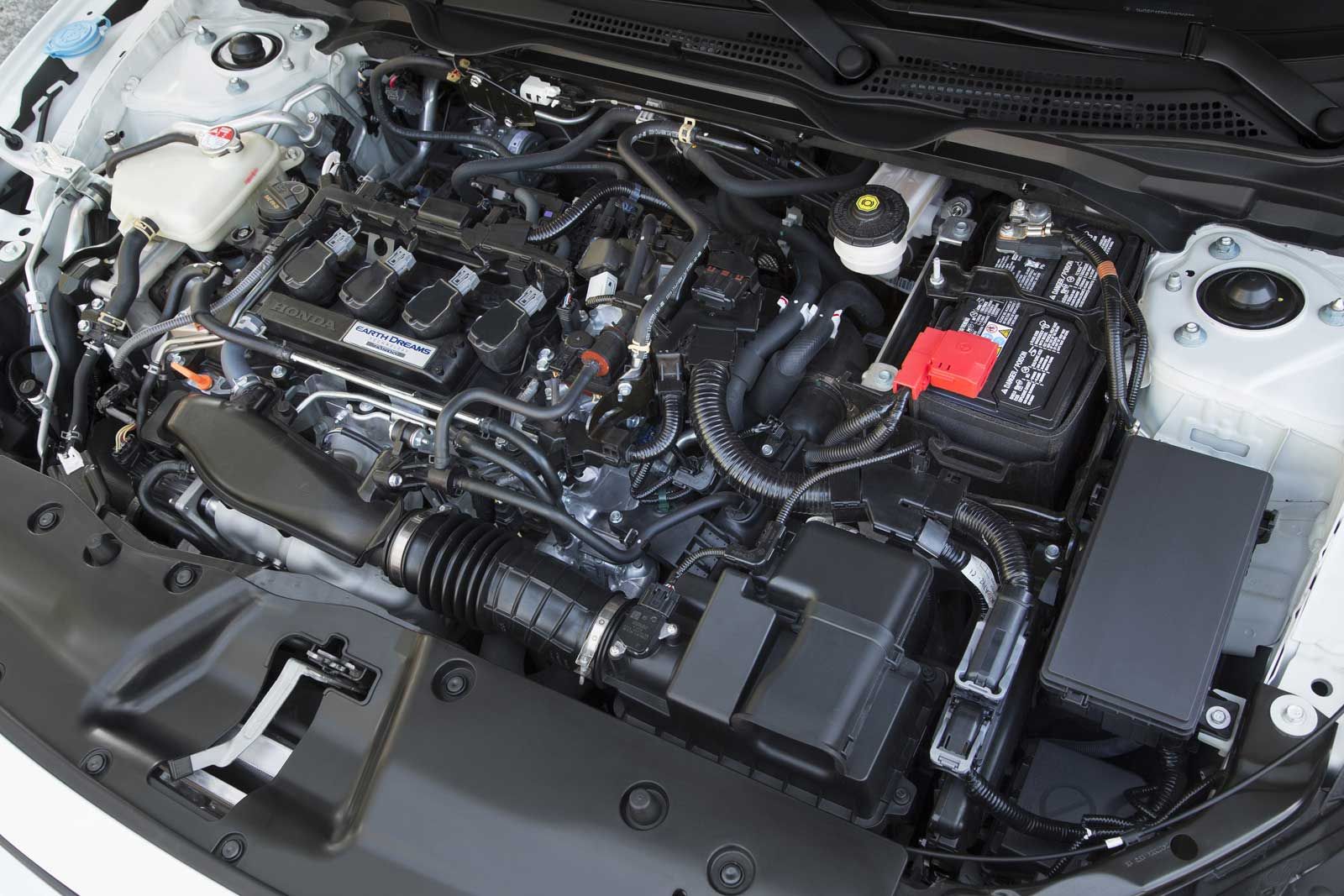

6 Benefits Of Turbo-Charged Petrol Engines

Turbochargers were primarily seen as diesel-oriented for a long time. That has come of age and now petrol engines that run on turbo algorithms are commonplace. Petrol-based turbo engines are preferred for their fuel economy, making them more environmentally friendly.

5 Turbocharger Failure Rate

It is not uncommon to encounter turbo engine failure because the more components there are interlinked in a functional engine block, the more it is prone to damage. At mileages beyond 100,000 miles, a turbo’s cylinder walls begin to exhibit gaps resulting from continual wear and tear over the period it has been in use. And the same applies to piston rings.

4 Symptoms Of A Failing Turbo And What To Do

Like in any other active mechanical device, turbochargers do give in with time. Symptoms of an ailing turbo include cracked casing, uneven bearing, and just about any tired component around the engine bracket. The turbo is repairable depending on the extent of the damage.

3 Turbo Failure: To Buy Or Replace?

Causes of turbo malfunctions come about due to poor oil lubrication plus a combination of exhaust contaminants that comprise soot and any debris that may get sucked into the turbo. Uneven exhaust blockage can add to turbo troubles. The question is whether to buy or replace a turbo. Typically, turbo parts cost around $2800 while the newly assembled unit costs over $4,000. It’s up to you to choose which option to take, of course depending on how much your turbo expert demands in repairs.

2 Turbo Compatibility With Ordinary Engines

A turbocharger is not directly compatible with ordinary gasoline engines, but it can be fitted into its place if space so allows. It is also possible with some modifications. With turbo engines, the best part is that you can increase its power output with no corresponding increase in weight.

1 2020-2024 Turbo Production Outlook

Today’s largest turbo engine makers include Borg Warner Inc, Mitsubishi Heavy Industries, Cummings Inc., and IHI Corporation. Whereas these industries produce turbines of all cadres, projections show increased demand for turbocharged engines from 2020 going forward. This is partly in fulfillment of federal legislation that demands stringent observance of carbon emissions even as manufacturers compete for fuel-efficient modules. Furthermore, the looming hike in oil prices expected post-Covid-19 pandemic will trigger consumer demand for fuel-efficient cars.