In 2020, everything shut down, and we had to shelter in place. One year later, we finally learned to cope with donning masks in public and working from home. And then came 2022, when we had to readjust to going back to office, and we learned to cope with our pre-pandemic routines.

All the while, the economy lost steam and the political fractions were blaming each other for supply chain issues, rising interest rates, lost jobs, inflation, and a staggering increase in gas prices. But when 2023 finally arrived, we had high hopes that the economy would stabilize and the future would once more look bright. Unfortunately, most economists don't share our enthusiasm, and they predict that the new year will bring significant problems.

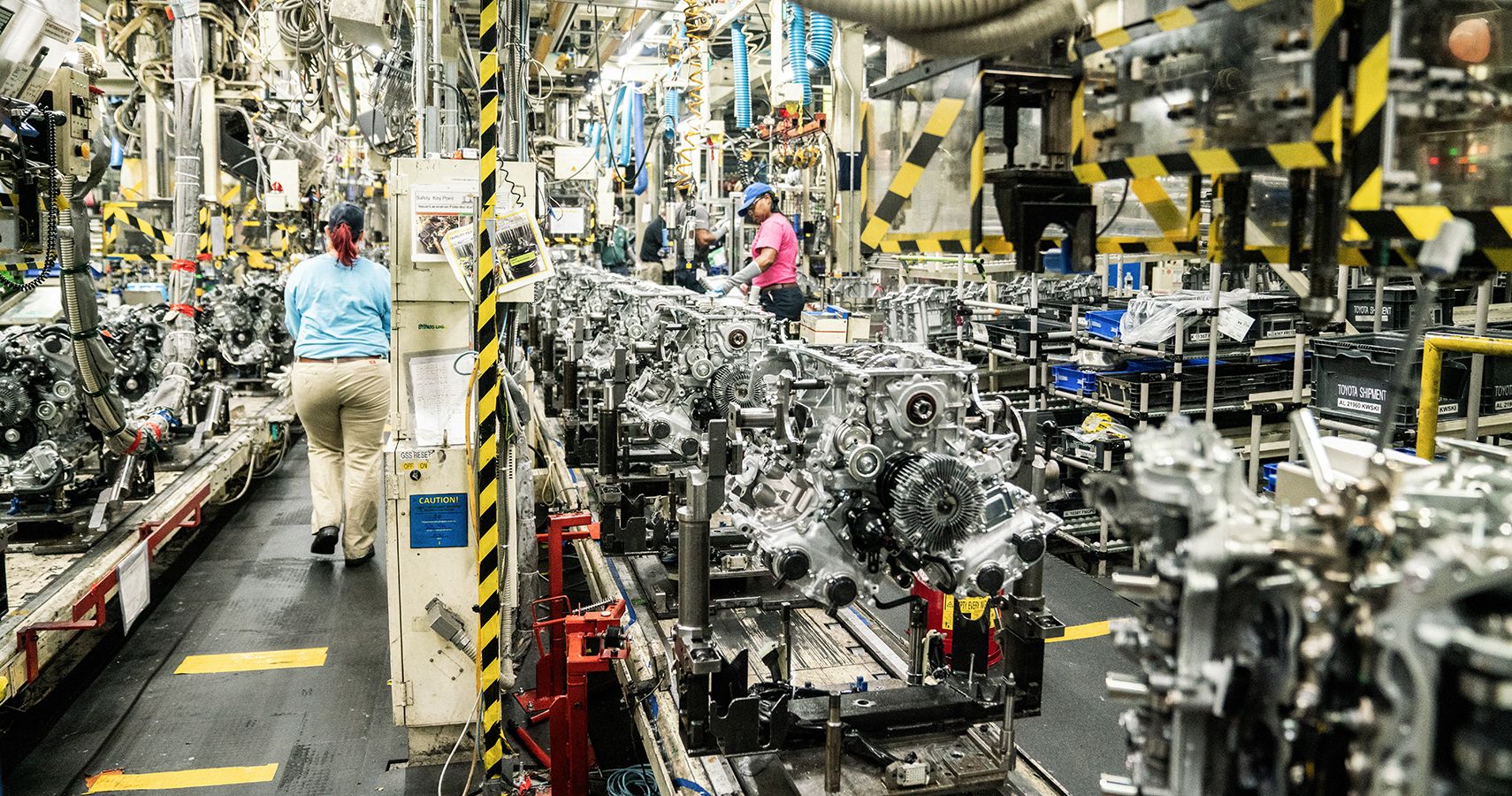

In particular, the auto industry has to get ready for a challenging year. Despite advancements, chip shortages and supply chain problems still exist. Moreover, inflation is hitting the brakes on consumption. And there’s also the issue of changing consumer habits that give automakers and dealers additional headaches. So, here's why 2023 may be another tough year for the auto industry.

The Auto Industry In 2023: The Auto Industry Should Prepare For Several Challenges

First, economic woes will continue to affect consumption. Car buyers will delay purchasing a vehicle until the market stabilizes or at least until prices come down. Meanwhile, supply chain disruptions will continue even in 2023, impacting both manufactures of electric vehicles and gas-powered cars.

“The chip shortage, in particular, could affect 2 million to 3 million vehicles in 2023, according to some estimates. The impact will be higher for EVs, as they use approximately 30 percent more chips than do ICEs,” says Vehicle Service Pros.

Naturally, if clients put off purchases, the difficulty for dealers will be how to move slow-moving inventory. This could have an even greater negative effect on the bottom line for some dealers, who already have a damaged reputation due to markups that happened during the pandemic. In the meantime, best-selling models and in-demand cars would continue to be expensive because these units will have limited inventory. Furthermore, the continuous supply chain bottlenecks would do nothing to alleviate the inventory problem. In essence, dealers and automakers must figure out how to solve two problems at once: how to sell vehicles that consumers don't want and how to deal with the shortage of popular models.

The Auto Industry In 2023: Demand May Increase Once More, But Profits Could Still Decrease Because Of Discounts

The automotive market won't return to normal even if demand for some popular models rises, so automakers will need to provide incentives and discounts. Evidently, discounts will lead to margin erosion. On top of that, automakers will have to deal with production cuts, rising raw material costs and shortages of materials, which will have a negative impact on their ability to turn a profit. In order to keep their profit margins intact, car manufacturers will have to turn to new tactics. For instance, Capital One says that the food business serves as a source of inspiration for the auto industry.

“An old trick used by the food industry goes like this: When a company’s profits are squeezed, it can compensate by giving you less for your money. By slightly lowering the number of, say, potato chips in a bag while charging the same price, it will sneak past most shoppers that what used to be a four-ounce bag of chips is now 3.5 ounces,” says Capital One. “Automakers have been paying attention. With material prices and pandemic-related supply chain snags pressuring production costs, some car companies have been thinking about how they can sell a smaller bag of chips.”

Capital One mentions the incident involving Rivian R1T and R1S. The EV company attempted to use this strategy, and it backfired horribly. According to the American bank holding, the EV trucks were meant to carry four motors that produced a combined 835 horsepower. Consumers even put down a $1,000 deposit for this arrangement. Then, in March, Rivian revealed significant revisions to its lineup, and buyers who had already paid a deposit learned their cars would now only have two motors that produced a combined 600 horsepower. Meanwhile, prices for the four motors vehicles rose by $12,000. It goes without saying that the blowback was tremendous, and some buyers canceled their orders. In a nutshell, automakers face a serious challenge in 2023: they need to overcome rising costs and persistent supply chain shortages, but they can't boost prices to keep their profit margins intact. At the same time, car manufacturers cannot adopt dubious strategies and tactics because doing so could lead to reputational crises and further alienate customers.

Sources: CNN, Vehicle Service Pros, Capital One