The Acura NSX supercar has recently made a comeback in a modern, high-performance form. Honda devoted $70 million to the construction of the NSX Performance Manufacturing Center, a 200,000 square foot factory in Marysville, Ohio. The factory employs around 100 engineers who have been highly acclaimed in their respective fields and thoroughly vetted for competency.

Thanks to the refined manufacturing philosophy that Acura implements at the factory, they have obtained 11 patents and international acclaim. “The openness of the space - expansive, airy, and absolutely pristine - aptly represents the values of transparency and collaboration here,” according to the automaker. Analysis of the factory substantiates these claims, thanks to the company's unique propensity for immaculate precision.

Production Of The Refined Acura NSX

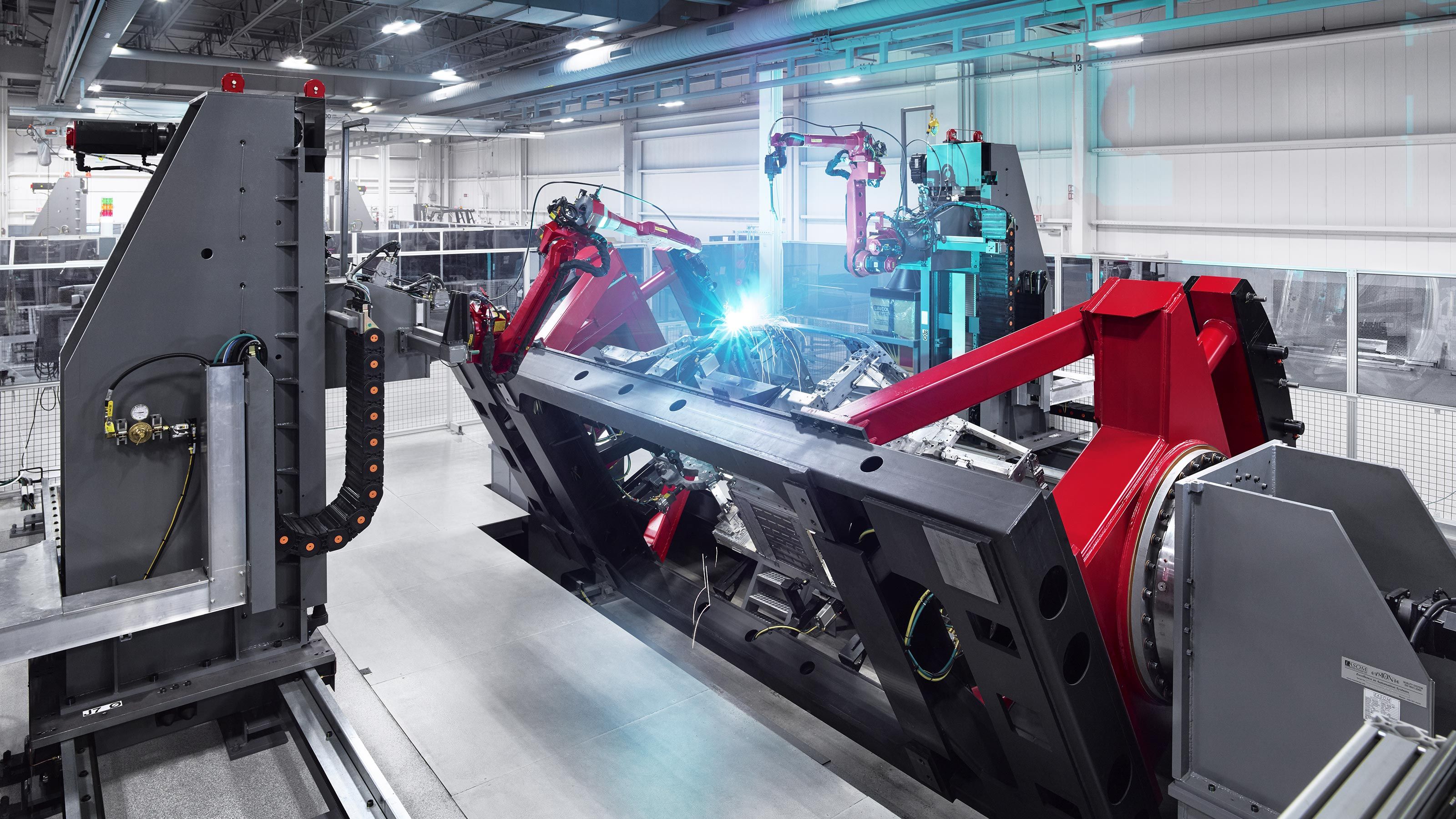

At the NSX assembly plant, precision is key; 2700 quality control markers are in place to ensure that every detail emerges with reliable accuracy. Specialists conduct inspections on those steps completed by robots and fix them by hand if they are deemed unsatisfactory. Although quality checkpoints are an inherent part of any factory, Acura takes it a step further with its meticulous attention to detail.

The 2020 NSX is a pioneer in its class, incorporating 3 electric motors with a 3.5L twin-turbo V6 and 9-speed dual-clutch transmission. Thanks to its hybrid power train, it is able to achieve an EPA combined gas mileage rating of 21mpg. MotorTrend named the 2020 NSX in the “Top 10 Quickest AWD Sports Cars From 0-60MPH Ever Tested By MotorTrend.” Its various modes allow users to seamlessly switch between quiet electric and the roar from its finely-tuned exhaust note. Its performance is impressive, producing 573 horsepower and 476 lb-ft of torque.

Among conversations with specialists, Acura has developed some new tools to enhance the factory experience. Instead of a grueling schedule, engineers enjoy a 4-day work week and an environment tuned to their specific preferences. The factory employs a combination of hand-crafted and robotic assembly.

Paint And Coatings

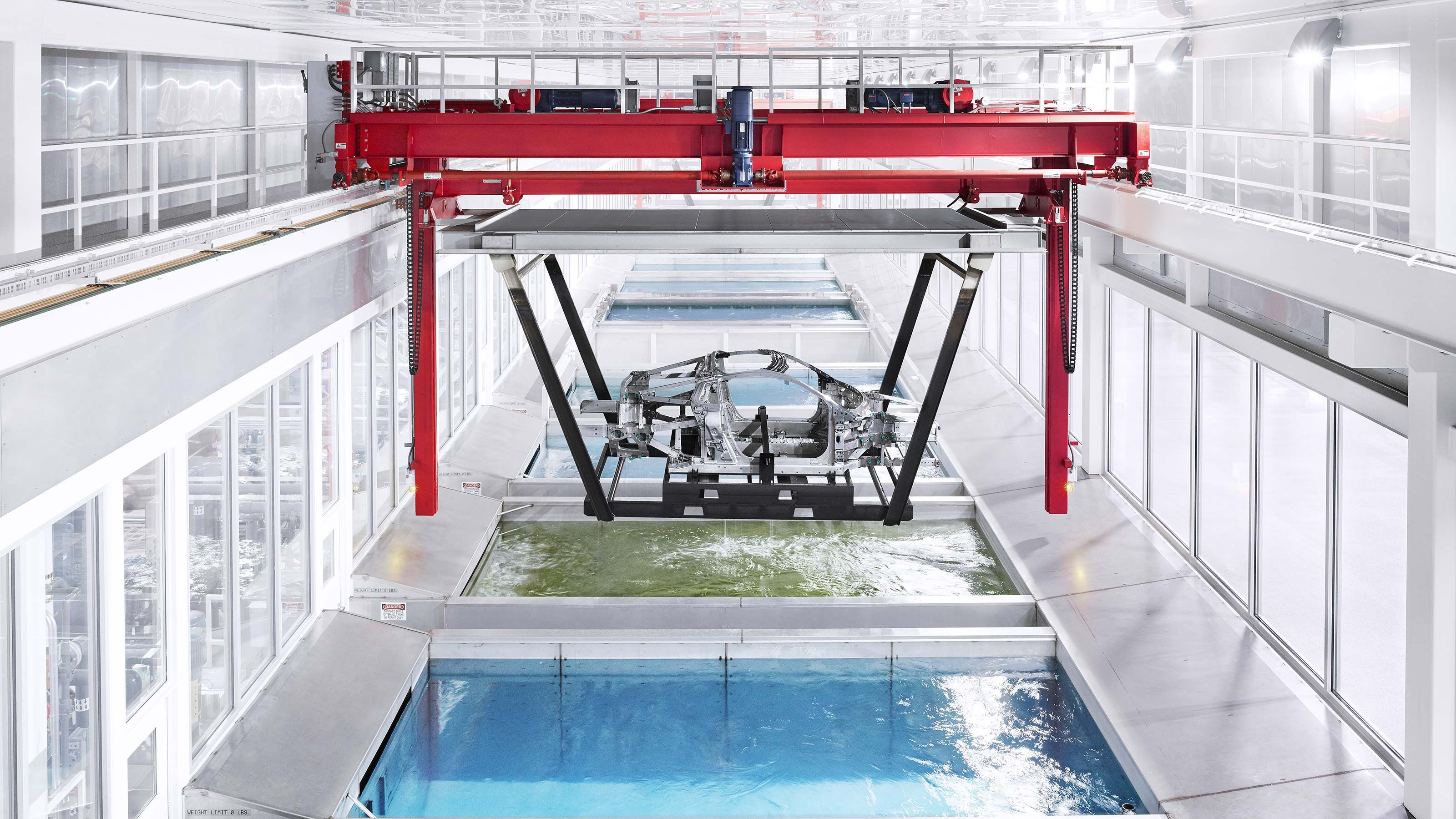

The paint process that goes into the NSX is incredibly distinguished. Each production car obtains its lustrous finish through steps that take more than 20 hours combined. Multiple dip-tanks enclosed in a glass chamber clean, rinse, and coat the car. Body panels are painted by robots while components such as the grille are hand-sprayed.

To prevent corrosion, a zirconium-based primer is used. This is one of the chemical choices that help Acura produce zero sludge waste as a byproduct of NSX manufacturing. In total, 11 coats of primer, paint, and clear coat are applied; Each coat is thoroughly inspected both by eye and laser.

Customers can choose from a variety of paint colors, ranging from Berlina Black to Thermal Orange. A higher tier option, which comes in “Nouvelle Blue Pearl” or “Valencia Red Pearl”, gets the Andaro treatment at PMC. Although these options add $6,000 to the NSX price tag, the treatment is worth the price.

Multiple clear coats are applied, including a tinted clear coat that gives the finish extra depth and UV shielding. At the end of the Andaro process, Acura achieves a paint thickness of 18 mils. For comparison, a typical factory paint job averages around 4-5 mils, making the Andaro paint relatively impenetrable.

Structural Assembly

Most panels that form structural elements of the car are created via stamping, extrusion, or hydro-forming before being transferred to the PMC. Many of these elements are joined using ablation casting, where parts are cast in sand before being cleaned and cooled by high powered water jets. Ablation casting is used on “crush zones” to reinforce the NSX chassis. Throughout the factory, robotic rotisseries are used to rotate the frame to provide easy access for robots and workers.

Mechanical Evaluation

The 3.5L V6 fitted to the NSX is hand-built and extensively tested in the Anna Engine Plant, located within the vicinity of PMC. Each engine is subjected to a 150-mile bench test and break-in to ensure all components and specs are correct.

Before leaving the factory, each NSX is tested on a dyno which includes evaluation of the exhaust sound, turbo system, and brakes. A unique feature of the car’s production is that it is fully tested inside the factory, eliminating the buildup of foreign substances or dirt prior to delivery. Each car is also sprayed with water to check for potential leaks.

Customer Satisfaction

Customization options ensure that each user can build a car to their personal taste. The automaker provides the opportunity for customers to observe their custom build as well as take tours of the PMC. “At PMC you will witness the finely tuned NSX production process,” the company states, “where master builders employ groundbreaking techniques that result in the ultimate expression of Acura Precision Crafted Performance." A focus on customer experience is just one of many features that make Honda's NSX factory distinguished among the competition.

Sources: Acura, Wired, MotorTrend