Porsche has been implementing novel sustainability strategies in their production facilities for years. According to the company, they have reduced CO2 emissions by more than 75% since 2014. The factory in Stuttgart-Zuffenhausen has seen many milestones, from their first car ever sold to the first carbon neutral Porsche. The automaker has constructed an addition to the legendary factory, designed primarily for carbon neutral production of the electric Taycan.

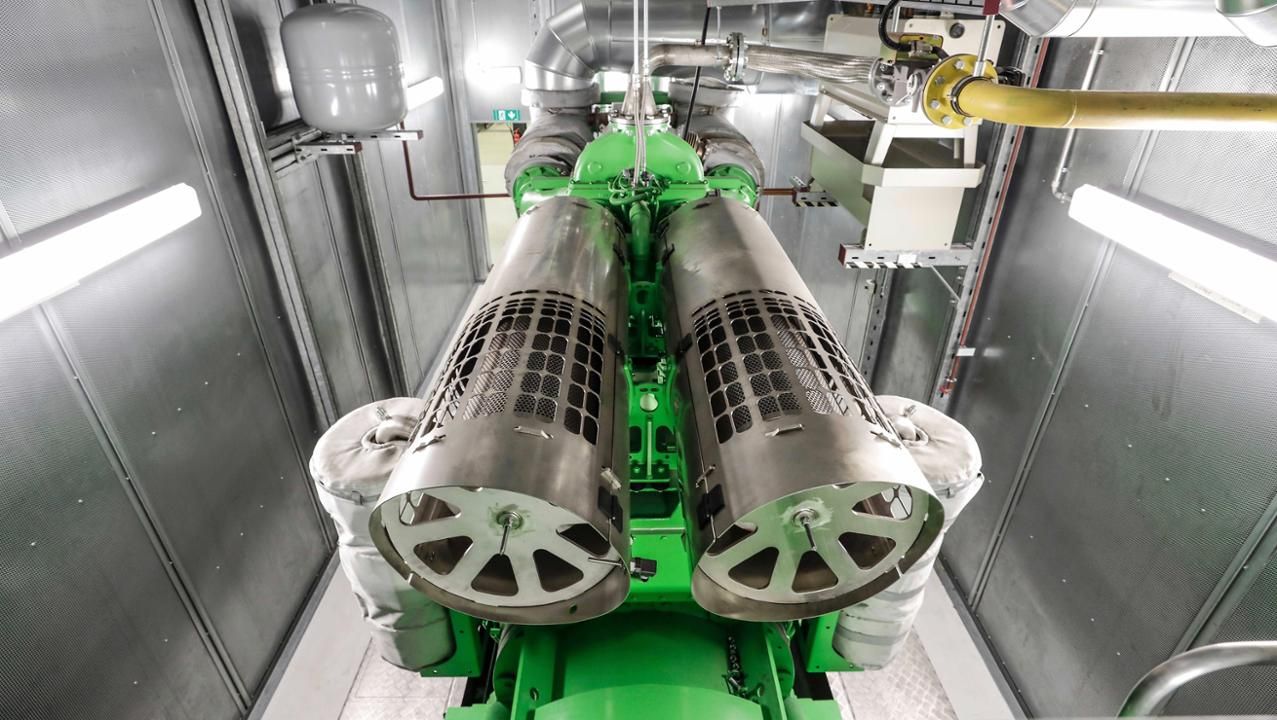

Amidst the construction, Porsche has designed policies that will help them reach a goal of “Zero Impact”. This is intended to progressively eliminate the negative environmental effects that can be a result of car production. They are committed to the use of renewable energy throughout their facilities, adding new plants that run on biogas to provide heat and energy.

Here’s the foundation of Porsche’s “Zero Impact” strategy and a look inside their new factory additions.

Porsche Manufacturing 4.0

Novel technologies are combined with ergonomic strategies as part of Porsche's Production 4.0. Through its new policies and facilities, Porsche aims to eliminate the negative effects of vehicle production on the environment.

The company has suggested 12 main tiers of improvement that encompass multiple categories of business operations. “Sustainability is the sum of many individual elements”, said production and logistics board member Albrecht Reimold. Porsche claims that the use of alternative energy has saved 23.3 gigawatt hours of electricity since 2015.

Efficient resource management and the prevention of costly operational disruptions are parts of the new initiative. Porsche intends to find optimal ways to increase production without harming the environment. “Perception” also plays into the strategy - According to the company, this is a dynamic factor that includes sustainability, the physical appearance of the factory and social environment within.

Porsche takes aim at environmental contamination by formulating processes for correctly handling waste and pollutant byproducts. Soil and water quality is factored into this equation, along with the preservation of biodiversity. If implemented, these policies will surpass most generic sustainability claims.

Zero Impact Goals

Porsche has been working on sustainability goals for quite some time. The production of the Macan and Panamera already derives some energy from a photovoltaic plant. They also use biomass power, with the Leipzig factory fueled by renewable energy sources. The factory uses Automatic Guided Vehicles (AGVs) to transport modules within the facility, much like those used by Lamborghini.

Carbon emissions aren’t the only thing that Porsche intends to improve upon. Efforts are made to increase worker comfort and efficiency within the factory while mitigating detrimental byproducts. Flow-drilling screws and the use of supportive exoskeletons help increase worker productivity.

A 110-degree swivel mount for cars on the production line allows workers to easily access the components without reaching overhead. “Our committment to sustainability goes well beyond decarbonization”, says Albrecht Reimold. To encourage biodiversity and wildlife preservation, they even allotted 326 acres to grazing land for animals outside Porsche Leipzig.

Efficiency & Green Logistics

Many components of the Porsche logistics system are powered by sustainable practices. Most vehicles and trains used to transport components are either electric or powered by renewable energy. This is a key element of the Green Logistics policy at Porsche.

They also seek to effectively integrate modern technologies while retaining the historical significance of their Zuffenhausen factory. “Porsche is committed to the traditional corporate headquarters and combines tradition with future”, according to the company.

Long-Term Sustainability

In recent years, the automaker has employed renewable energy sources such as biogas and solar. In addition to the production of heat and electricity from organic waste, Porsche was the first in the world to build a photovoltaic pylon. The 37-ton, 82’ structure has the solar capacity to power a Porsche center. The monument, which generates up to 30,000kWh of electricity, also serves as a reminder of the company’s committment to sustainability.

Porsche projects the main goals of improvement in three words: Green, Lean, and Smart. If environmental health can be successfully integrated with the efficient use of resources, transparent networking and optimized processes, Porsche will be closer to achieving this zero impact trifecta.

Factory Of The Future

A new paint shop and 900 meter (~2952 ft) conveyor bridge facilitate finishing and transporting Porsche components. Construction materials were recycled during the addition of new facilities. Interestingly, the company has been testing surfaces that can absorb and break down toxic nitrogen dioxide (NOx).

Amidst the release of the all-electric Taycan Turbo / Turbo S, the zero impact goals are not going unnoticed. According to Porsche, over 700 million euros (over $8 million USD) will be devoted to Taycan production.

The automaker originally claimed that the Taycan would add 1,500 jobs. After the initial surge in consumer demand, Porsche added 500 additional jobs for a total of 2,000. At Zuffenhausen, production of the Taycan will be completely carbon neutral with an anticipated production of 20,000 vehicles per year.

Sources: Porsche, Volkswagen AG, Medium