At its core an intercooler is basically a simple heat exchange, but when you look closer you will notice that it can be a little more complicated than that and there are a couple very different types of intercoolers.

The most common type of intercooler is an air-to-air intercooler, which you will find on just about any modern turbo or supercharged car. It is the more affordable option, aside from ditching the intercooler, but that will eventually result in overheating, as most early adopters discovered in the 70s and 80s. The other type of intercooler is an air-to-water intercooler, something usually reserved for high performance applications, it is significantly more efficient but also far more expensive to produce.

Why Intercoolers Are Important

Although overheating is one issue commonly associated with forced induction cars that are not equipped with an intercooler, it wasn’t actually the main problem.

The biggest battle was a loss of efficiency, as the hot gasses got compressed the performance benefits seen from compressing them in the first place were lost upon combustion. Cool air carries more oxygen than hot air and that ratio would eventually become the same, meaning the naturally aspirated vehicle would end up making the same power as the forced induction vehicle, in extreme cases the equivalent naturally aspirated vehicle might even make more power depending on how much mechanical drag is caused by the turbo or supercharger.

That is not the only issue with superheated air, the emissions will also increase, mitigating one of the other supposed benefits of forced induction. In many ways the intercooler was the missing piece of the puzzle for forced induction engines.

The Air-To-Air Intercooler

As the name might suggest this type of intercooler uses cooler ambient air to cool the hot compressed air coming from the turbo or supercharger.

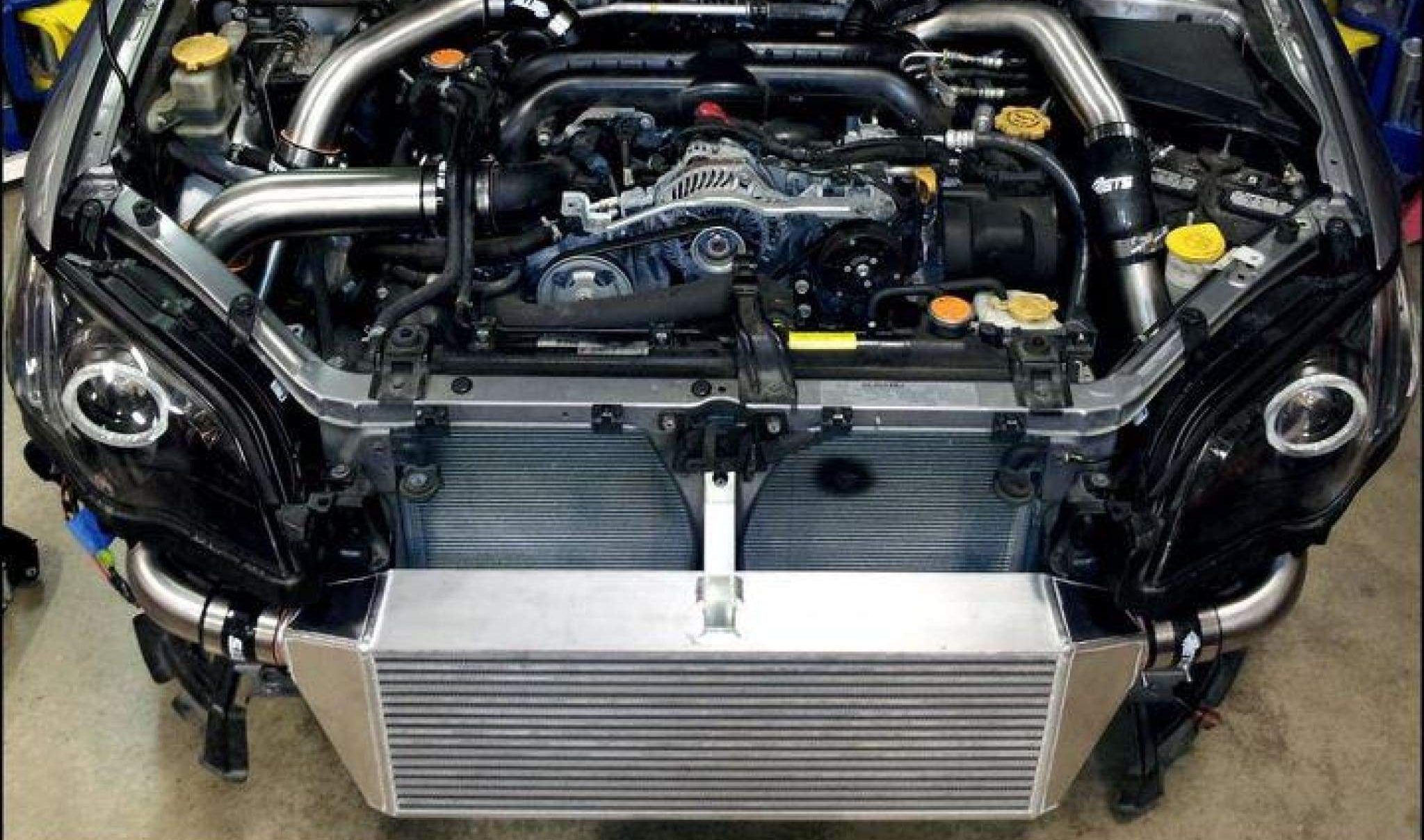

They are made much like any radiator or heat exchange device, with the hot air passing by the cool air that absorbs some of the heat. It is crucial that the device is mounted in an area where there is maximum airflow, if not, the intercooler will basically become redundant. The cooler compressed air not only increases efficiency but also horsepower.

It is worth noting that the engineering of these devices plays a big part in what sort of performance gains can be had, that is why fitting an aftermarket alternative has become a popular upgrade. Unfortunately if the aftermarket intercooler is mounted incorrectly or the engineering is substandard, it will have the opposite effect, reducing, instead of increasing horsepower and may even damage the engine.

The Air-To-Water Intercooler

As is the case with most performance related components this development can be credited to motorsport.

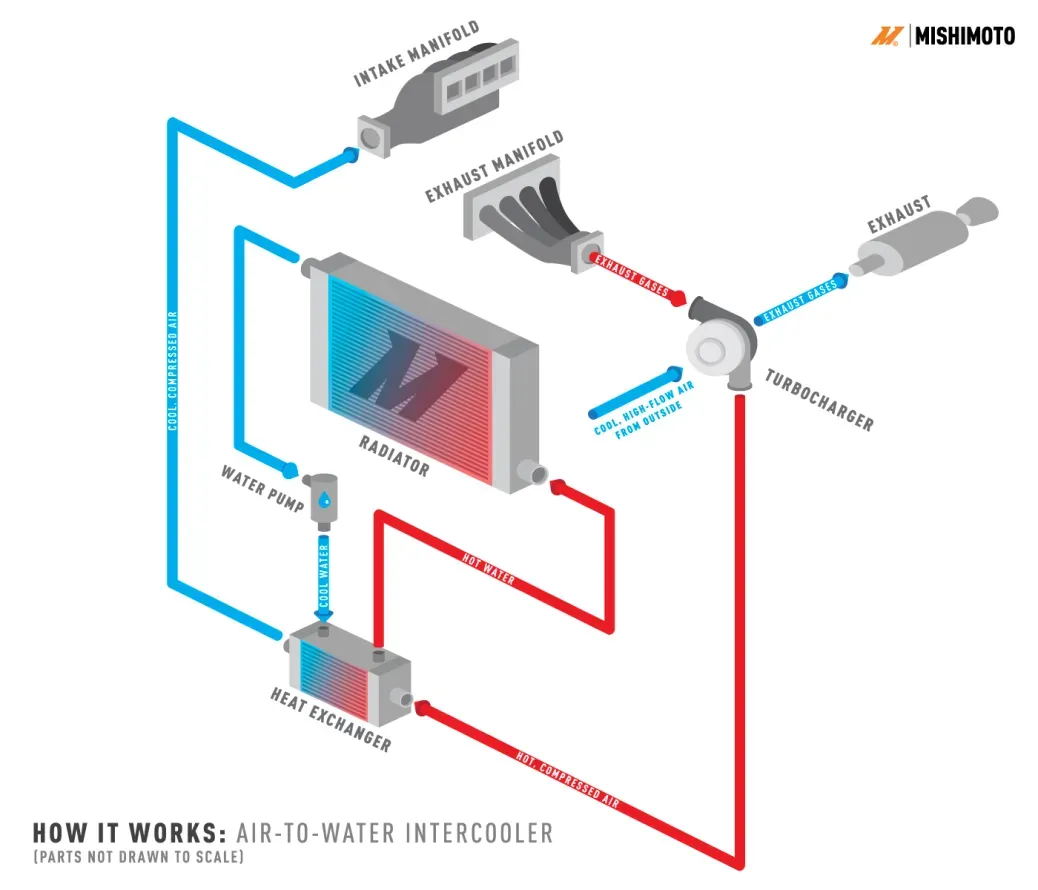

The air-to-water intercooler works more or less the same as a radiator, just instead of the air just cooling the water, there is a second stage where the water or in most cases coolant, cools the compressed air from the turbo or supercharger. It goes without saying that this is both more efficient in creating power and more expensive to run. With so many more components it is also a lot more expensive to manufacture, the aftermarket is also not going to be of much use for a system like this as so much engineering goes into it any modification would likely decrease performance unless you replace the entire system.

The weight added is always off-set by the performance gains, but as the cost goes up the benefits of installing this kind of system are mitigated by the extra maintenance costs, making the air-to-air system more popular for mass-produced cars.