Everyone’s aware of the Corvette’s contribution to the motoring scene. For those who don’t, the legacy of Corvette spans eight generations, with the most recent being the first-ever mid-engined design. The 2022 Chevrolet Corvette C8 had quite the reception since its launch not too long ago. Its impressive performance at a relatively accessible price meant the Corvette C8 was quick to gain popularity, with demand overpowering supply even today.

The Corvette moniker created quite an impact when General Motors launched it back in 1953. With its timeless curves, the Chevrolet Corvette managed to instill a sense of desire in the minds of every American irrespective of age. A similar buzz, the one reminiscent of 1953, was felt when GM officially revealed the mighty C8 Z06.

However, this is not the usual Z06 exercise that we know of. What the C8 Z06 has that none of its predecessors could ever dream of is a bespoke-flat-plane gem of a V8. Yes, the 2023 Z06 ditches the pushrod design in favor of a bespoke LT6 high-revving V8. But what prompted Chevrolet for such a move? Let's find out.

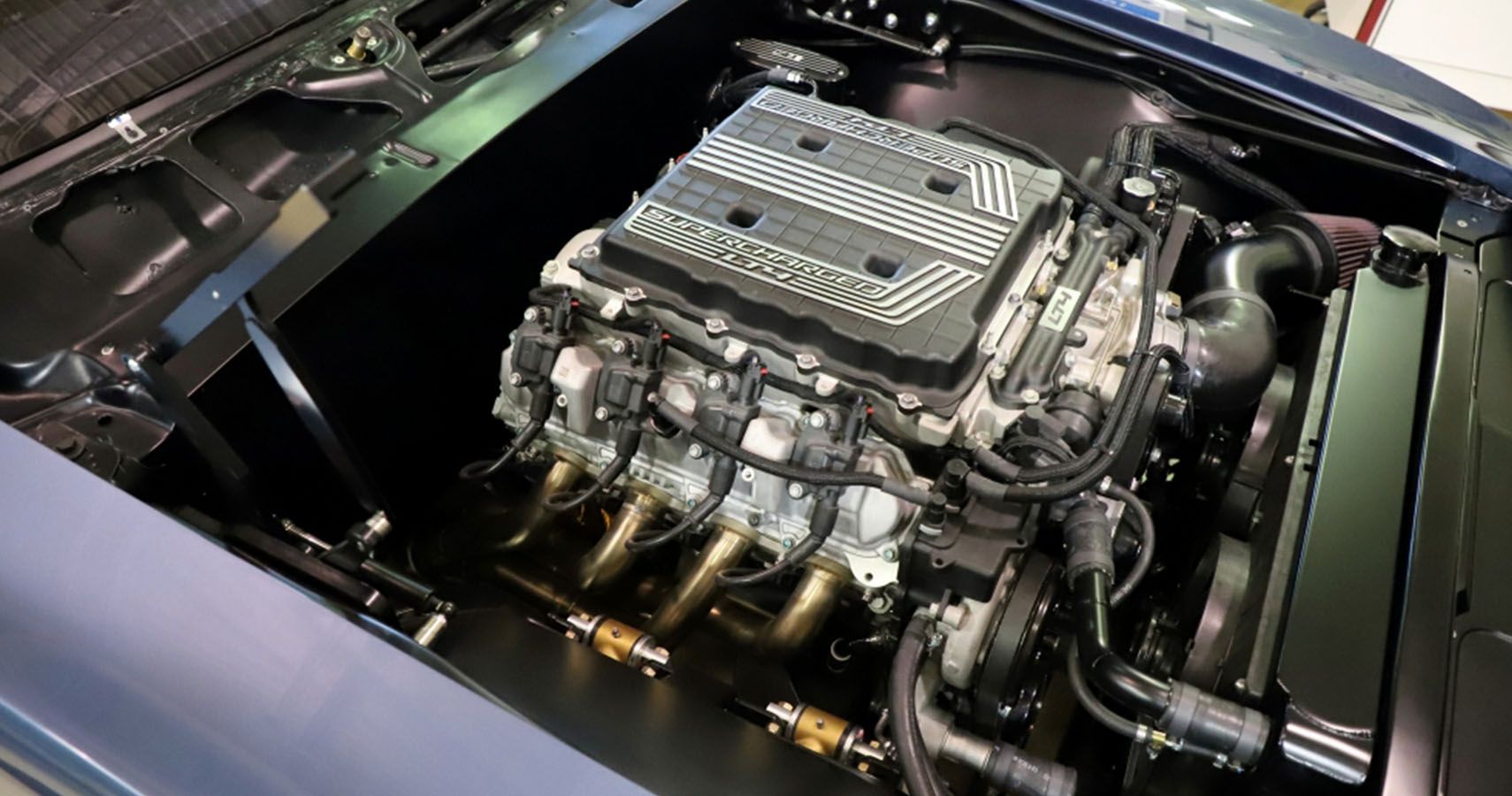

GM’s New Dual Overhead Cam LT6 Replaces The LT4 Pushrod V8

The new 2023 C8 Z06 uses a hand-built 5.5-liter flat-plane crank naturally aspirated V8, dubbed the LT6. The engine is totally bespoke to the 2023 Z06, and you won’t find it in any other Chevy or GM product. Power figures stand at 670 horsepower with 460 lb-ft of torque. A host of engineering wizardry has gone into this new screamer of a V8. We’ll discuss the particulars in the following sections. Oh, and the LT6 engine in the 2023 C8 Z06 also happens to be the most powerful naturally aspirated production V8 in existence.

The C7 Corvette Z06 came with a new 6.2-liter Supercharged V8, dubbed the LT4 powertrain. Power stood at 650 horsepower and 650 lb-ft of torque. Several improvements were brought into the motor, which was essentially an LS small block V8, albeit a newer generation. The 6.2 featured direct injection, variable valve timing, and an active fuel management system to enhance performance and efficiency. Although the LT4 and LT6 are no slouch, they behave in two very different ways. One’s about maximum attack, while the other has a sense of duality in mind.

What Was The Driving Force Behind Dropping The Pushrod V8?

The answer is less rotational inertia, better response, and trackability. If you know your engines, you’ll be aware of pushrod engines and their inability to sustain high revs. In a pushrod V8, valves are actuated via rockers connected to a pushrod that gets inputs from a single camshaft. Between the valves and the camshaft are many components that are arranged such that high engine revs could overstress their intricate movements and result in valve float. To be more specific, the pushrod exhibits a reciprocating motion, which has relatively more resistance or inertia than circular motion. To eliminate the inertial forces and make way for a meatier top end, GM engineers decided to go the DOHC route, ditching the pushrod design.

Let’s Take A Closer Look At The LT4 and LT6 Architecture

The LT4 was designed specifically to handle the additional stresses induced by forced induction. The higher output meant the internals had to be strong to function for longer periods. Most notable were the adoption of Rotocast T6 aluminum cylinder heads that are much stronger and better at heat dissipation than conventional aluminum heads. Having forged connecting rods helped increase tensile strength and reduce reciprocating inertia, leading to efficient power delivery.

Utilizing lightweight titanium valves meant shaving unwanted reciprocating mass and reduced valve float during high rpms. Although, it wasn’t entirely eliminated, owing to the pushrod design. The introduction of direct fuel injection meant the LT4 could run a higher 10:1 compression ratio, relatively high for a forced-induction motor. In addition to this, forged aluminum pistons in the LT4 meant better material strength and less inertial forces during piston movements.

As for the LT6, the engine’s signature feature is a crankshaft with four throws located in a single plane. The layout is commonly called “flat”—versus the usual 90 degrees of a traditional, “cross-plane” V8. The key to the LT6’s performance capability is a lightweight, low-inertia rotating assembly with a short stroke design, allowing for an 8,600 rpm redline. What you’ll find inside are forged aluminum pistons and forged titanium connecting rods for low mass and high strength. Titanium intake and sodium-filled exhaust valves are available along with dual-coil valve springs for sustained performance. The engine runs a 12.5:1 compression, allowing the LT6 to offer excellent volumetric efficiency. Also worth mentioning is the LT6’s all-new active split intake manifold. This allows the Z06 to consume more than one atmospheric pressure despite its naturally aspirated design.

Sources: Chevrolet