The feud between Ford and Fiat-Chrysler for off-roading supremacy has evolved into an all-out war of one-upmanship recently. But no matter how amazing the powerful Ford F-150 Raptor and the Ram TRX or the electronically disconnecting sway bars on the Jeep Wrangler and revived Bronco might sound, the truth is that these factory off-roaders still leave new buyers wanting more.

In the world of off-roading, and especially overlanding, the laundry list of upgrades required to elevate a stock 4x4 into a trail-ready rig can quickly escalate well into the six-figure range. After all, a brand-new Jeep Wrangler or Gladiator in Rubicon trim can easily cost $60,000 or more, all by itself.

But a company called EarthCruiser operating out of Bend, Oregon, has pre-empted that entire process by building a setup that’s ready to hit the trail immediately. EarthCruiser has enjoyed a big few months recently, unveiling a DIY overlanding chassis called the CORE, and dual-cab variants of their FX and EXP models.

I recently got the chance to speak with EarthCruiser's founder and CEO Lance Gillies and his Engineering Department Manager, Austin Steimer, about the company’s off-roading origins and how they've led to a product lineup that very well might include the best overlanding rigs available on the market today.

EarthCruiser Founder & CEO Lance Gillies

Gillies hails from Australia, where he founded EarthCruiser on April Fool’s Day of 2008. But going further back, his entire life has been all about four-wheeling.

Gillies fondly recalls his earliest days on the road, saying, “My earliest childhood memories were traveling somewhere in the middle of Australia, which is to me just a wonderful way to grow up because you’re always seeing something new. You get very adaptable, don’t ever get too comfortable, and it keeps you very curious.”

That nomadic lifestyle meant Gillies didn’t get much in the way of a formal education, though he did prove quite adept with his hands early on, taking every opportunity to tinker at a young age.

“I was the kid who took the washing machine apart because I discovered it had a gearbox,” he said, “So I quickly attached the washing machine gearbox to a ride-on lawnmower so the lawnmower could go faster.”

Gillies grew up into a highly experienced off-roading adult, taking the knowledge he’d absorbed over the years and applying it to fun projects that kept his tinkerer’s mindset engaged. His early career included working on just about everything imaginable—but merely welding cow-tossers and fabricating tow bars wasn’t enough to keep him engaged. He found his mind needed a bit more of a challenge after relatively simple projects modifying Toyota Land Cruisers and Nissan Patrols with goodies like welded differentials.

The challenge he required eventually materialized in building bush-ready firetrucks and high-security prison transport vans.

Gillies dove into the complexities of putting together a 4x4 that could haul prisoners safely and reliably across Australia, saying, “It had to be tricky... We were dealing with all kinds of interesting people who had nothing but time on their hands and we had to continually outsmart them.”

Fast forward a few years and Gillies found himself on the island of Borneo competing in the Rainforest Challenge, which is essentially an off-road rally that requires entrants to bring their own vehicle and food while conquering extreme four-wheeling obstacles on a stopwatch—24 hours a day for two whole weeks.

In that rugged environment, Gillies met fellow Aussie Michelle Boltz, who he would later marry and who would help nudge him in the direction of developing the original EarthCruiser.

Back in Australia, Gillies and Boltz decided they wanted to build an off-roader that could comfortably haul them wherever they might possibly feel like going. A roadblock quickly emerged, however, in the form of Australia’s strict vehicle manufacturing and production laws, known as ADR (Australia Design Rules). ADR meant that building the first EarthCruiser would be quite a challenge.

Starting The EarthCruiser Build

That challenge sounded perfect in Gillies’ mind. He explained ADR to me, saying, “Australia does not care if you’re going to be a vehicle manufacturer that builds one vehicle or if you’re Toyota. The rules are the same.”

And if Australia didn’t have a rule in place for a specific part? Well, then the strictest standards of the EU and Germany would apply. It took Gillies 18 months to build the vehicle that would become EarthCruiser’s first prototype—a 700-kilometer test drive across the Outback quickly ensued.

After some more tinkering, that first EarthCruiser was put through a more significant 27,000-km torture test across Russia and Mongolia, including two passes on the "Road of Bones," a swamp-and-tundra trek from Yakutsk to Magadan—talk about things escalating quickly.

But Gillies could be confident in the vehicle because of the difficulty surrounding every decision he’d made throughout the process of getting it legalized. And that’s where EarthCruiser’s mindset shines through: every little detail has been painstakingly examined from every possible angle to produce what Gillies believes is the best overlander in the world.

Choosing The Chassis

For starters, the chassis used by EarthCruiser is a Mitsubishi Fuso cab-over built in concert with Mercedes-Benz and selected from a wide range of potential options including the Unimog and Toyota's ubiquitous Land Cruiser, plus other cab-overs from Isuzu, Hino, and MAN. How did Gillies narrow down the list?

“You build the vehicle around the tires, from the tires up,” he explained, and the second-place Isuzu chassis used 17.5-inch wheels from the factory, which wasn’t ideal when it came to finding rugged off-roading tires with good traction.

Plus, the Fuso is sold in something like 70 countries, making it easy to source parts and find service when things go wrong—in Gillies’ mind, things are going to go wrong, no matter what.

Just imagine breaking a windshield on an expedition in a third-world country where English is a distant third language. Well, there’s a good chance Mercedes-Benz and Mitsubishis abound, so local mechanics will be able to get to work immediately (or, at least, relatively soonish).

Now, a Toyota Land Cruiser might just be the number-one most ubiquitous off-roader in the world, but Gillies didn't think the chassis was up to his standards. "Using a Land Cruiser or something like that, we could never get the weight distribution properly, you’re always fighting it," whereas the Fuso, he said, "...Is a light commercial truck with a cab-over platform. We knew the weight capacity, we could never wear them out because we’re never taxing them.”

Small Enough To Park Easily In The City

The Fuso and the Isuzu chassis both made the shortlist because they used 12-volt electrical systems, as opposed to 24-volt—but the Fuso chassis didn’t come without its own set of challenges.

The commercial cab-over layout employs duallies at the rear axle, which isn't ideal for off-road traction. Another goal for the original EarthCruiser design was that it would fit in a shipping container, so narrowing the rear track became doubly important. Throw in the hope that the overlander could park in a normal city parking spot and the duallies simply had to go.

Gillies needed to convert the Fuso to single hubs. Due to ADR standards, though, he also needed to not just prove through testing that single tires could handle the stress and load of accelerating and braking, but he also needed a tire manufacturer to state in a letter that their tires were up to the task.

Wheels And Tires For Any Situation On Earth

Michelin came through in the crunch and provided the necessary paperwork (though EarthCruiser has since moved on to equipping Toyo tires). I asked Gillies what else came into the mix while transforming a Fuso work truck into an off-roader. Specifically, what kind of suspension mods?

His response was, quite simply, “Everything.”

Everything took serious work. For starters, the Fuso needed to ride higher to allow for the clearance of 37-inch tires (it comes with 32s from the factory). But that meant the headlights were all of a sudden higher—which required another round of modifications to comply with ADR light-pattern regulations.

Everything from the cab’s seat-mount bolts to the flame-proof materials, even the spare-wheel jack, required compliancing before Gillies could legally claim the EarthCruiser was ready for the road. The process meant, he said, “We literally destroyed a perfectly good cab of a Fuso truck... All about safety.”

Interior Design Decisions

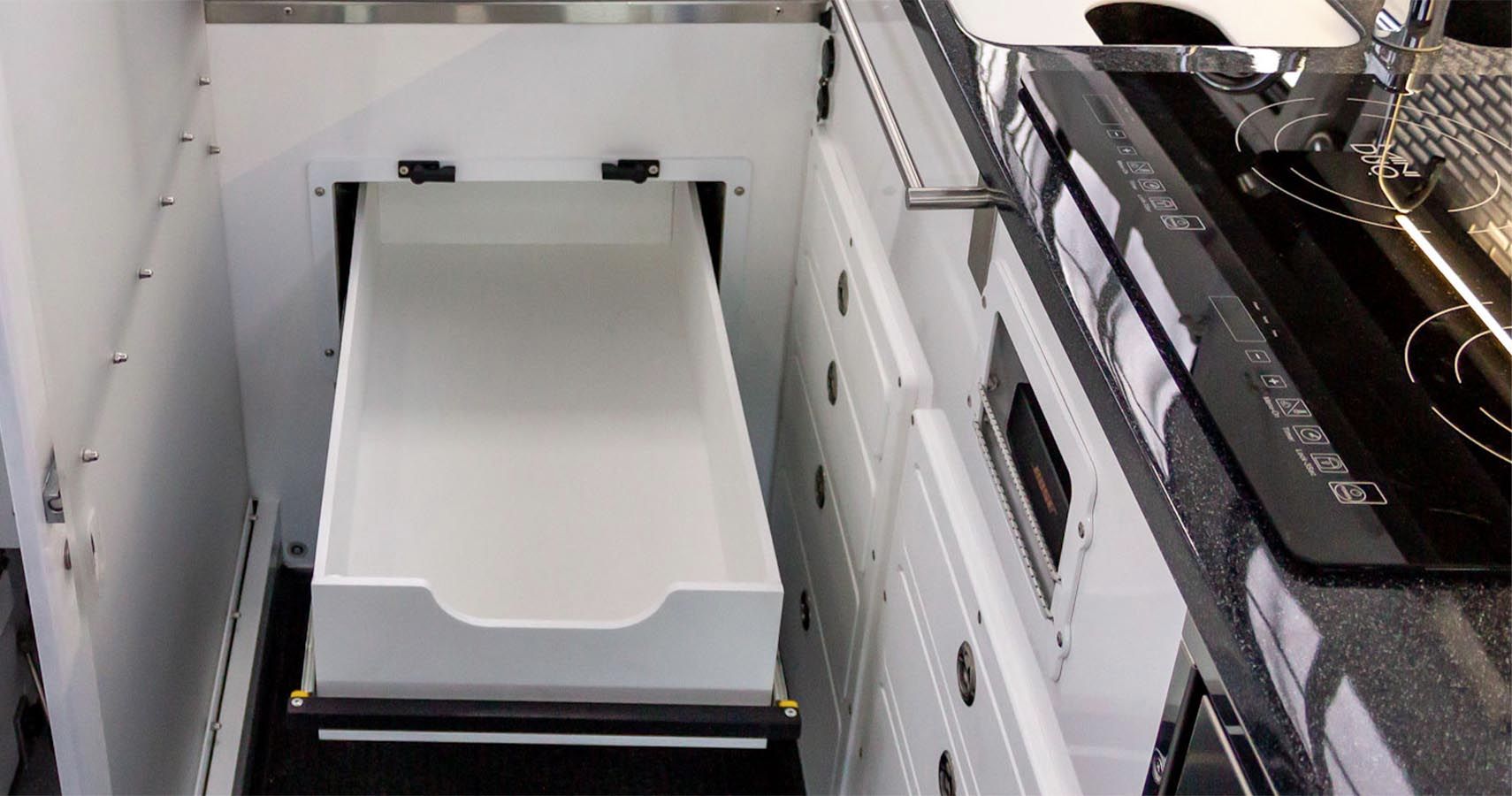

The interior, meanwhile, has been purposefully designed so that nothing moves or unlocks—not even the beer in the fridge gets foamy—when an EarthCruiser travels down rough roads. The exterior’s design demanded deep thought, as well, with the result being that all the surfaces are as smooth as possible, to prevent damage while navigating tight spaces between rocks or trees.

After all the back-and-forth, Gillies told me the legal situation is now straightforward: “It’s no longer a converted truck. As far as they’re concerned, it never was a truck. What it is now, in the eyes of the federal government, is an EarthCruiser.”

EarthCruiser's build standards are so detailed, in fact, that a customer was driving along on the Autobahn in Germany and hit a roadblock where police inspected the vehicle for legal compliance—it passed, no problem.

Everything You Need, Right At Hand

I wanted to know more about the actual mechanicals that went into the EarthCruiser build. At this point, Austin Steimer stepped in as EarthCruiser’s Engineering Department Manager operating out of EarthCruiser's US headquarters in Bend, Oregon (Gillies had to divest from EarthCruiser Australia shortly after he took EarthCruiser to Oregon in 2010).

Steimer has a military background, having served in the Marines, and then attended Oregon State after mustering out, where he earned an engineering degree. Where Gillies had covered the EarthCruiser’s ethos and conceptual evolution, Steimer went a little deeper into the real-world development process.

As he puts it, “The very best truck that we ever built is the next truck, because we’re always getting better.”

For example, on that complex suspension system, EarthCruiser is now, he says, “On rev G or F of our leaf springs—and we’re always trying to make them a little bit better.”

Choosing Between Front, Rear, And Four-Wheel Drive

EarthCruiser's Fuso chassis employs a General Motors Vortec V8 producing 297 horsepower and 361 lb-ft of torque, which is routed to an Allison 1000 six-speed automatic gearbox. From there, the Fuso chassis has also acquired a rather unique two-speed transfer case that allows the engine to power the front, the rear, or all four wheels.

I inquired why EarthCruiser chose such a special setup.

“What’s really the benefit of it?”

Steimer responded, “Well, it turns out that the front dig is really popular with anyone that has to deal with heavy snow. If you’re in a snowplow or an EarthCruiser and you need to get out, oftentimes it’s worse to have the rear wheels spinning. So you want to be able to get that front end and get it out.”

He went on to explain that he approaches projects with “...The end goal in mind first. Make sure the basics work, and from there, get the bells and whistles.”

Those bells and whistles don’t get too complex, though. I specifically pointed to Jeep and Ford’s popular electronically disconnecting sway bar systems. Not likely, said Steimer.

“Having the most capable overland vehicle in the world doesn’t just mean that it can get over the next set of terrain but it’s also got to be really serviceable—and not just serviceable by EarthCruiser but also by Fuso shops... But if you’ve got six or seven parts connected to an axle that are not usually on a Fuso, that service team is gonna say ‘No way, we’re not touching this thing.’”

All told, over seven years of suspension development have gone into the leaf springs, bushings, and shackles—all of which, Steimer assures me, have proven themselves, “More than capable.”

For EarthCruiser, it’s the end goal that matters. In this case, Gillies added as the conversation wrapped up, “Simple is good. Simple is really good. We wanted the most effective progressive rate suspension we could figure out, so each leaf—the length, the thickness, the temper, all that stuff—was very deliberate to strike the balance between happily zooming down the highway at 60 miles per hour and getting onto a corrugated road and happily zooming along that at 60 miles per hour.”

And when the going gets tough, Gillies said, “We’re not a return-to-base vehicle. We don’t do turn-around and we don’t do give up.”

Sources: earthcruiser.com, touratech.com, and motorbiscuit.com.