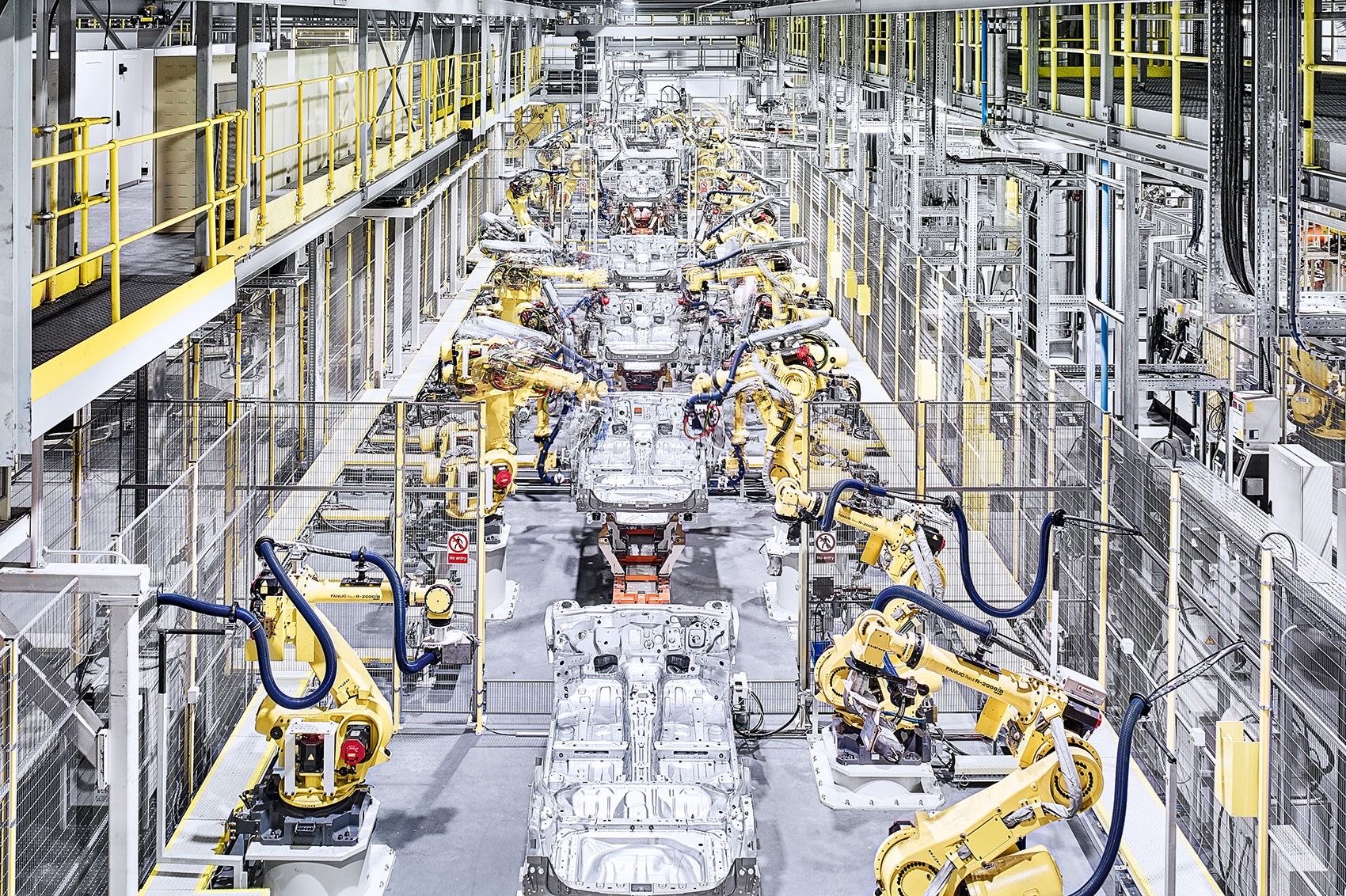

What would cars be without car factories? Would cars even exist without those huge, smoking, and noisy plants? The answers are: there wouldn’t be any cars. The automotive industry began in 1860 with the horseless carriages and it later developed into a competition between the US and Japan, the two pillars of the market.

Car factories are a bit of a mystery. We all know what comes out of them but have little clue what goes on inside. Here are some surprising problems car factories deal with every day as well as some amazing facts about how they operate that very few people know about.

10 Ugly: Supply Outstrips Demand

This is still true in the Covid-19 world. Simply, car factories manufacture too many vehicles. Production never slows, but demand does. The automotive industry produces over 60 million models per year and it employs 4 million people. In 2020, these businesses accounted for 6.1 percent of European workers. Because car factories are so crucial in the economy, they can never stop manufacturing. “Why not shut some factories?” asks Autocar.

The answer is competitiveness. Automakers focus on competing with each other, to launch the latest and greatest vehicle. Manufacturers don’t stop to wonder if there is a market for those cars; they just do it.

9 Beautiful: Exoskeleton Suits

Technological innovations don’t all go into in the vehicles. Plants are just as avant-garde and stylish. The exoskeleton suits some employees wear are proof. What are they? They are wearable machines that enhance the abilities of the people who use them and these suits provide support and reduce fatigue. This wearable technology targets the ugly reality more and more manufacturers face aging. As workers get older and retire, young people don’t work in car plants.

The suits are designed to help people hold and lift heavy equipment and they are powered by a lithium battery that has a life of about six to eight hours. Gulf News reports that manufacturers such as Honda, Ford, and General Motors are already using exoskeleton suits.

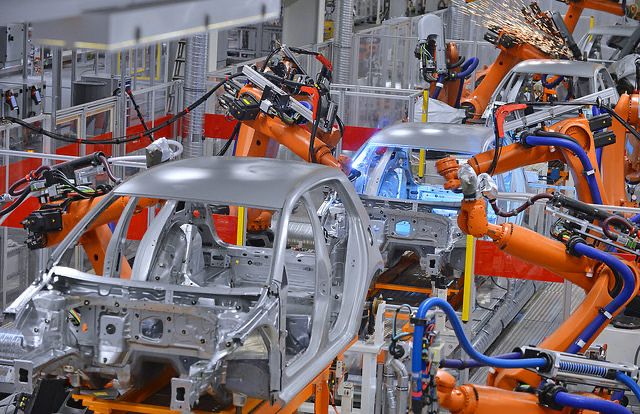

8 Ugly: The Impact On The Environment

Car factories are huge, smokey, noisy, and polluting. The majority of the pollution comes from fuel consumption and emissions of air pollution, and greenhouse gases, as National Geographic reports. The factories create Sulfur dioxide (SO2), a pollutant created by burning sulfur-containing fuels, especially diesel and coal. Between 2013 and 2017, the number of cars produced increased from 11.9 million to 17 million, causing a greater environmental impact.

While the energy consumption per car produced decreased by almost 16% over the last 10 years, the industry has a long way to go, since there are still 39 different kinds of plastic in a car.

7 Beautiful: General Motors Factory Zero

To reverse the not so eco-friendly trend of the automotive industry, General Motors took a promising step. Instead of closing down the factory at Detroit-Hamtramck, the manufacturer is turning it into an electric-vehicle sole production. This decision is both a promising step and a challenge. Factory Zero will employ about 2,200 workers with an initial investment of $2.2 billion.

As CNN reports, this new plant doesn’t only manufacture environment-conscious vehicles, but it also aims to reduce its footprint. Factory Zero will have a 30-kilowatt solar carport and a 516-kilowatt ground-mounted solar panel array and it will have a 16.5-acre wildlife habitat. A step in the right direction.

6 Ugly: The Covid-19 Closures

Coronavirus had an impact on everyone’s life and work, and the automotive industry is no exception. Car sales have dropped and factories have been shutting down. The Detroit Free Press reports that the city's Big Three have agreed to close US plants. Ford, General Motors, and FCA agreed on the strategy as a precaution against Covid-19. The constantly-changing rules around lockdowns and shutdowns make the survival of car factories a gamble. Uncertainty leads to fear, which leads to public pressure. Manufacturers such as Fiat Chrysler and Honda have been asked to close their factories, more as a precaution than as a surrender.

A necessary precaution as CNBC reports, since “many employees are missing work and many employees on sick leave are perfectly healthy, but they’ve been exposed to the virus and are missing work because they have to self-quarantine for 14 days.”

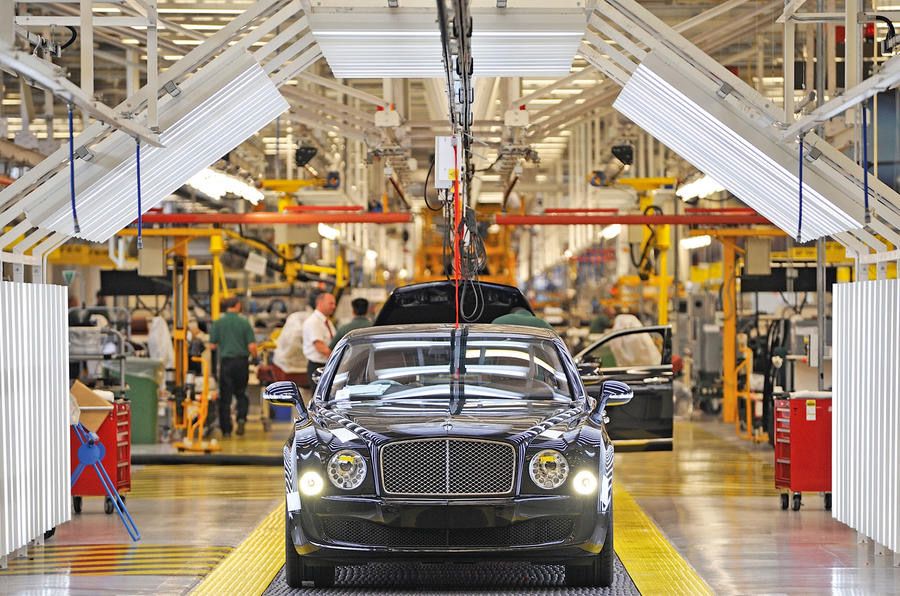

5 Beautiful: The Morgan Factory In Malvern, England

Morgan Motor Company is a positive example of a car factory. The idea of the company was born in 1881 although its first hit was the 1909 Morgan Three-Wheeler. These vehicles have an ash wood frame, aluminum, and leather. Morgan’s cars are handmade and they endure extensive physical testing. In 2020, the English manufacturer gave up on the steel chassis and substituted it with aluminum.

Morgan is the example of a family business with a worldwide reputation, designing innovative and glamorous vehicles. And raising funds for Coronavirus relief.

4 Ugly: Not Ready For EVs

GM’s Factory Zero is an exception in the automotive industry. The majority of factories aren’t ready for the production of electric cars. Dave Leggett, editor of the car industry website Just-Auto said to BBC: “A lot of carmakers are not ready to deliver electric vehicles at the right quantities," said Leggett, “they need to change their operations and gear the cars much more to a mass market, but that requires investment.”

Manufacturers are also worried about what the shift to EVs production means to employees and employers. Since a lot of the components of modern vehicles (especially engines) won’t be needed anyway, specific jobs and competencies will go away.

3 Beautiful: Car Parts Made From Cannabis

Innovation doesn’t stop because car plants are not ready. Technology doesn’t stop because the automotive industry isn’t eco-friendly. It’s to address these issues that researchers are working on plastic from cannabis, to reduce the industry’s carbon footprint. Wojciech Komala, a research and development director, talked to BBC about this project.

“We lower the carbon footprint by using bio-based sources," Komala said. "And by trying to develop lighter components for the cars." In the laboratories, researchers are synthesizing polymers to produce eco-friendly bioplastics.

2 Ugly: Workers Don’t Share Their Experience

There aren’t many interviews with employees of car plants and workers in these factories don’t tell their stories. The factories seem an impenetrable fortress, filled with strong walls and secrets. The most recent investigation into the conditions of people in car plants is from a 2017 The Guardian article. The English newspaper looked into the conditions at a Tesla factory and the results were a bag of mixed feelings. Employees described rough conditions in which workers were passing out in the production line and people are taken away in ambulances.

“I’ve seen people pass out, hit the floor like a pancake and smash their face open,” said Jonathan Galescu, a production technician at Tesla said to The Guardian, “they just send us to work around him while he’s still lying on the floor.” It’s been three years since any employee from any car manufacturer has spoken.

1 Beautiful: The Japanese Recovery After The Earthquake

In 2011, Japan was destroyed by an earthquake and then by a tsunami. The aftermath of the chaos hit the industry as much as the people. Car manufacturers suffered, especially due to their “Just in time” philosophy. The strategy of Japanese automakers use only materials housed in the factory to make sure inventory levels were kept low and investment in in-process inventories was at a minimum.

After 2011, Japan’s automotive industry stuck to its philosophy and, still, it recovered slowly, but surely. Until Japan became the third car manufacturer in the world, with 9.5 million total vehicles in 2018, or 10% of all vehicles made.

Car factories are a whole universe in the automotive industry. They are innovative yet old fashioned, they are stylish yet polluting. They are secretive.