Singing the praises of its newest production facility, German automaker Mercedes-Benz announced that its first all-electric sedan, the EQS, has rolled off the production line at Factory 56. The EQS is the EV version of the company’s flagship S-Class sedan and will be a showcase vehicle for Mercedes’ plans beyond internal combustion engines (ICE). Located in Sindelfingen, near the company’s Stuttgart headquarters, Factory 56 is already producing ICE-powered S-Class and Maybach S-Class sedans.

Mercedes Factory 56 Focuses On Sustainability

Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG remarks, "The future of our global Mercedes-Benz production network begins with EQS production in Factory 56: this future is CO2-neutral, sustainable, fully digitalized, connected and highly flexible. The start of production of the EQS is a highlight in our unprecedented electric vehicle initiative in the production area. In 2022, a total of eight Mercedes-EQ electric vehicles will be produced at seven locations on three continents."

At about 237,000 sq ft or the size of 30 soccer fields, Factory 56 represents a departure for Mercedes as the facility is designed around production flexibility rather than focused on only a limited number or range of models. The 95-year-old carmaker must adapt to the changing world of auto production while maintaining leading positions in technology and premium vehicles.

Factory 56 Will Be Able To Produce Mercedes Of All Sizes

According to the company, Factory 56’s most important feature is maximum flexibility. On only one level, Factory 56 can perform all assembly steps for vehicles of different designs and drive systems – from conventional to all-electric drive. The assembly hall is 100 percent flexible so that all Mercedes models can enter production in the quickest possible time, depending on demand – from compact vehicles to SUVs.

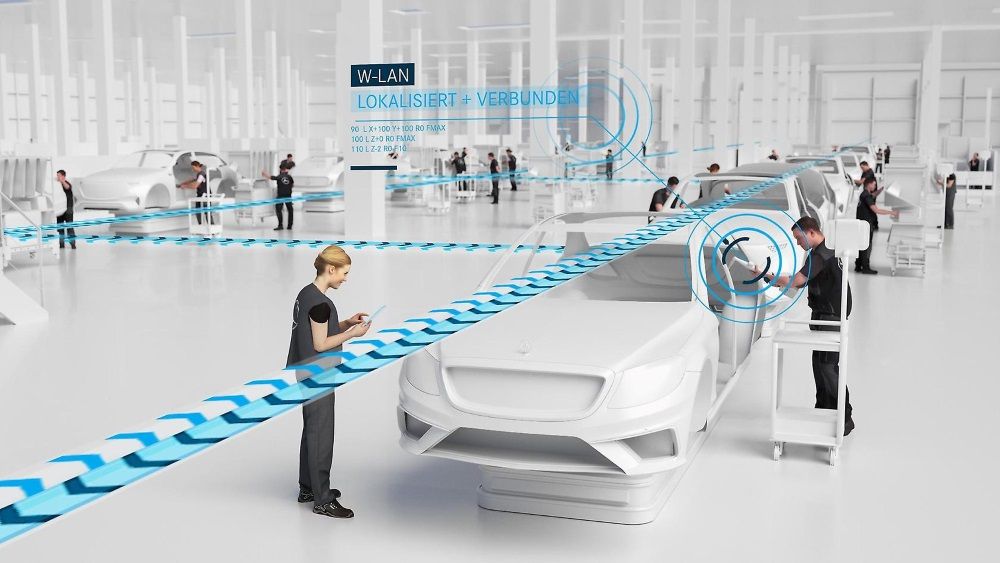

Mercedes will use two “TecLines” to avoid fixed production points and increase flexibility at this factory. With TecLines, say the company, the traditional assembly line is replaced by a driverless transport system that will move each vehicle through the build process. To introduce a new car or production process, the factory only needs to update the route of the automated guided vehicle AGV. Mercedes reports that more the 400 AGVs are in use at Factory 56.

A Milestone In The Company’s Corporate History

“Factory 56 is not only a milestone in Daimler’s corporate history, but also an important commitment to Baden-Württemberg as a location for the mobility industry. The factory stands for state-of-the-art standards – both in production and in products. Digitization and decarbonization are top priorities,” said Winfried Kretschmann, Minister President of Baden-Württemberg, during the opening of the facility last September.

Source: Mercedes-Benz