The increasing abundance of electric vehicles or other devices that depend directly on batteries makes manufacturers research how much new technologies can increase battery performance.

Since the mid-20th century, researchers have come a long way to develop stable, affordable, and long-lasting batteries. The research of these power suppliers goes through the development of new materials and composites. But before continuing with the story, we must know what a battery is like inside.

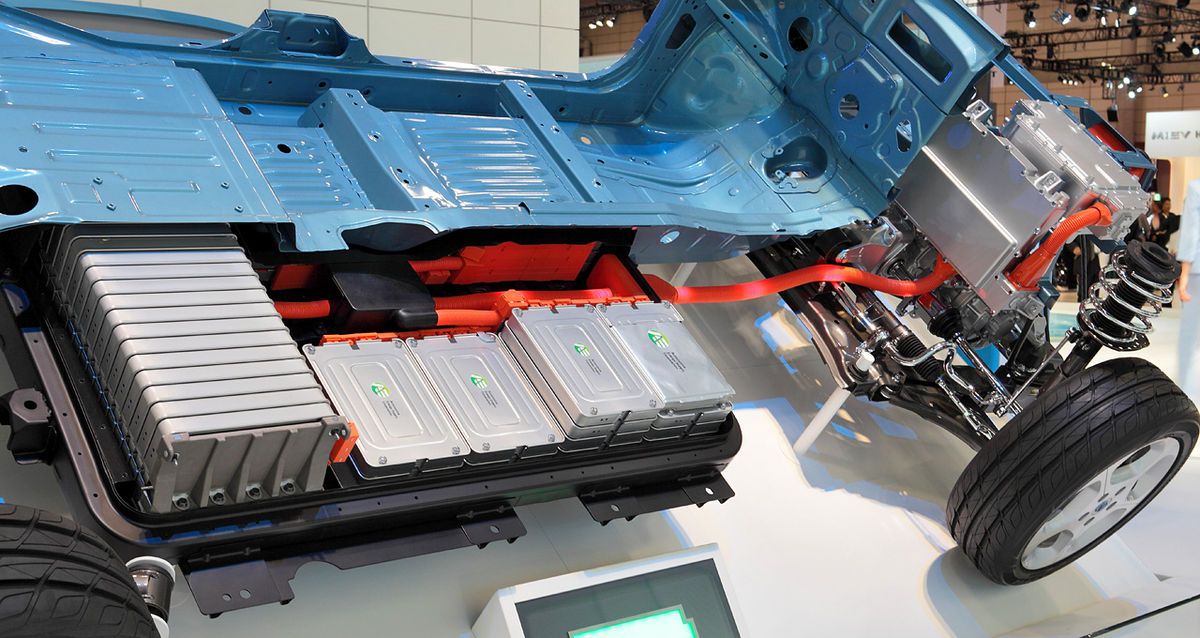

All batteries comprise four fundamental components: two electrodes called anode and cathode, a liquid electrolyte where the ions that store energy move, and a separator that prevents the electrodes from coming into direct contact with each other.

When we charge the battery of our smartphone, car, or any other device, what happens is that the ions and their liquid electrolyte flow towards the anode. As the battery discharges, it means that these have moved towards the cathode side.

But how can we determine whether a battery is good or bad? First, of course, this is directly related to the amount of energy it can store, in short: the capacity of the battery. But also, the relationship between the speed of battery charging, the cycles it can withstand, and the time it takes to discharge is what determines the quality of a battery. Logically, this also determines the price tag on the battery.

The Democratization Of Batteries

The cost of batteries has evolved rapidly, democratizing in a much more pronounced way than other current technologies have been able to do. For example, in 2010, we used to pay up to more than six times than today for the same product. Eleven years ago, the price per kilowatt-hour (kWh) was about 1,100 dollars; today, we can buy such an amount for just under $180. Over the next decade, we expect this price to decrease by half. This drop can result in a much lower cost of purchasing electric vehicles than a similar fossil fuel alternative in our daily lives.

To know the beginnings of the lithium-ion battery, we must go back to the 1970s. The lithium metal used at that time for the anode caused fires, so its danger was high. As the years progressed, manufacturers started researching new materials based on cobalt.

The latter gave greater stability and life to the battery. Finally, during the 1990s, Keizaburo Tozawa, director of Sony's battery division, brought together these innovations and patented the first commercial lithium-ion battery.

Types Of Batteries Used In The EV Industry

These materials are still necessary for the manufacture of our batteries, which has caused some of them, such as lithium, to skyrocket in the market price. That is why many companies are looking for a more affordable alternative to these materials, such as nickel, manganese, or iron. In the battery market, when a component is cheaper, it means that its performance is significantly lower, leading manufacturers to continue developing three main formulas: Nickel, manganese, and cobalt oxide (NMC) Nickel, cobalt, and aluminum oxide (NCA), and Lithium iron phosphate (LFP).

In the beginning, researchers wanted to do without using cobalt, but this wasn’t possible. However, using the NMC formula considerably reduced its integration since the compound that formed nickel oxide and manganese increased the capabilities of cobalt alone.

After a few years of research, chemists succeeded in thickening the anode and cathode material and recombining the formula so that they could further dispense with cobalt and nickel. This improvement helped to increase the storage of even more lithium ions, which impacted an improvement in the energy of the said battery, increasing its autonomy and reducing its price.

The EV Battery Revolution

In 2012, the electric vehicle brand Tesla came to revolutionize the market for these cars by reformulating the components of their batteries. The Americans, together with their partner Panasonic, innovated to introduce aluminum. This reformulation further dispensed with the use of cobalt and lowered purchase and sale costs. Tesla has invested millions of dollars in the chemical research of new materials, which has resulted in an improvement in the range of its vehicles compared to other competent brands.

These researchers found that adding silicon oxide slightly to the formula reduced the use of graphite and helped reduce the battery's overall weight without sacrificing performance and further lowering costs. This innovation was first introduced by the Tesla Model 3 in 2017.

Nowadays the goal that researchers are pursuing is to stop using cobalt altogether. For this purpose, the formula of LFP (lithium-ferrophosphate) was arrived at, which uses iron, a considerably cheaper material. Unfortunately, although the procedure worked on paper, the truth is that it could not store as many lithium ions as in the alternatives that used cobalt.

However, the LFP did find its way by installing itself in vehicles such as taxis or buses since they require inexpensive batteries and large ones in the case of buses. For this reason, this type of technology became an alternative type of vehicle - and a larger size. Thus, today they are used, although the formulas described above continue to demonstrate their superiority.

The Future Is Solid-State

Currently, the research and development of new types of batteries are moving towards the so-called solid-state batteries. Its name refers to the fact that it uses solid lithium between the anode and the cathode.

However, this material has taken years of chemical engineering since it could become unstable and cause spontaneous combustion when exposed to high levels of work. This is mainly because inside, it can form threads called dendrites, capable of passing through the separator and touching the cathode, culminating in a short circuit.

Research is taking the path of using solid electrolytes to replace the liquid inside, hence its name, solid-state battery, which eliminates the possibility of forming so-called dendrites. Currently, it's a material that does not include any risk since this new type of battery is advertised as one of the safest due to its zero risk of fire.

The introduction of these new batteries is expected to occur during the second half of this decade. These batteries will represent a notable leap in the performance of electric car batteries, with an increase in autonomy and charging times.

.jpg)