With a total of 176 wins, they’re third on the all-time list of F1 victories behind Ferrari and Mercedes Benz. For more than six decades, they’ve supplied engines to championship-winning cars in countless formulas and series the world over. Today, with operations in its native England and in the U.S., Cosworth remains an iconic name, not only in motorsport but in the automotive world, in general.

For a large part of their history, Cosworth was funded by Ford, and because of that, it’s the Ford name we sometimes see in the history books, but it’s the Cosworth engineering genius, regardless of who owned the bank account, that produced these fabulous power plants.

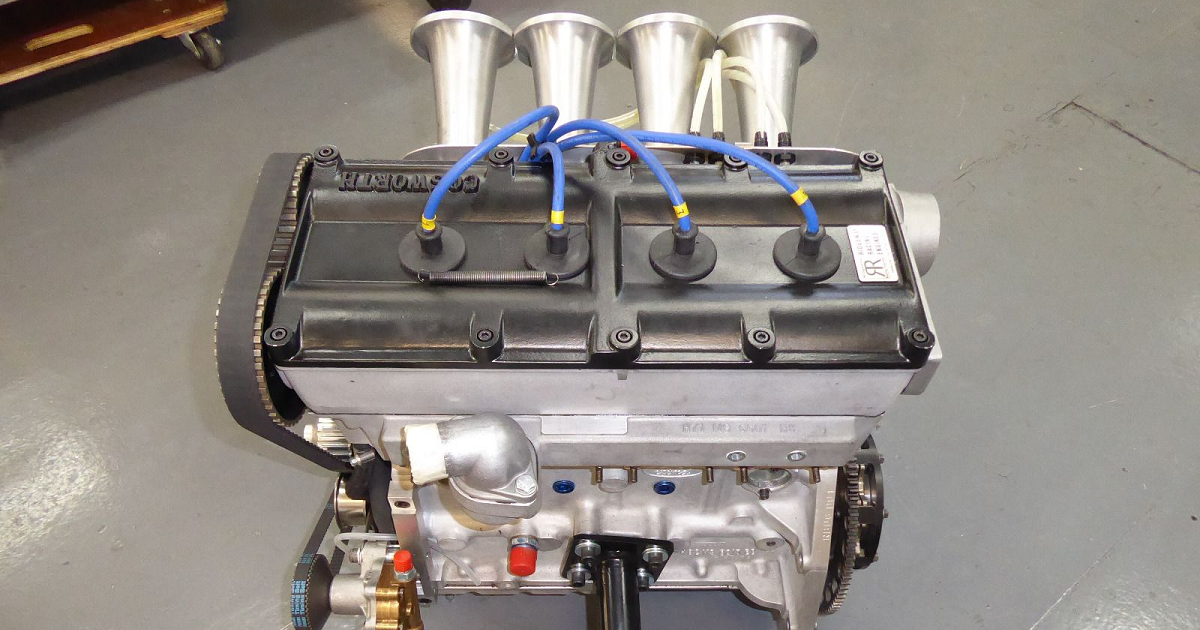

The famous DFV – Double Four Valve – V8 is Cosworth’s most successful F1 motor but the mill that is arguably the company’s most versatile is the BD Series. Developed initially in association with Ford and launched in 1969, the BDA was intended for use in the racing versions of Ford’s Escort road cars. The design brief was a simple one: a four-cylinder motor with more power than the rival Lotus-Ford unit.

Let's take a closer look at the BD series.

The BD Series: where it all began.

The BDA – BD for Belt Drive and A for series A – was based on Ford’s Kent cylinder block and was Cosworth’s first mass-produced road car engine. The biggest design difference between the donor engine and finished product was that the cam belt connected the crankshaft to twin overhead camshafts, superseding the Kent’s cam-in-block design. In accordance with the FIA’s Group 2 (Touring Cars) and Group 4 (Sports Cars) technical regulations for either road racing or rally cars, for which this engine was developed, the BDA was 1601cc.

The BD series starts to grow

In 1970, the BDB was developed as the power plant for the Escort RS1600 and was upgraded to 1701cc, and the BDC morphed out of that engine with added fuel injection. But the BDA was not dead. In 1972, Formula 2‘s regulations opened the door for BD engines to be used in single-seater racing. As engine sizes in Formula 2, however, were quickly increased to 2000cc and the BMW motors began to dominate. The need for progress with the BDs was obvious.

The BDE was increased to 1790cc, the BDF grew to 1927cc, and, in 1973, the BDG had been bored out to 1975cc. By this time, the limitations of the existing iron block had been reached, and the BDG became the first BD motor with a bespoke aluminum block. By this time, the motor was producing 280bhp, revving to 9250rpm, and boasted a compression ratio of 12:1.

To put that in context, Honda’s 2l VTEC, released with the brilliant S2000 in 1999, produced 237hp at 8300rpm. Granted, that motor came with a 60 000mi. factory warranty, but it gives you an idea of what Cosworth’s people were capable of.

BDH and J were once again based with the iron block and reduced in cubic capacity for the SCCA Formula C and sports car series. In 1975, a big-valve, fuel-injected BDM was built for Formula Atlantic, and a “sealed engine” version of this iteration, named BDN, was used in the 1977 Canadian Formula Atlantic. Both of these motors were producing north of 210bhp from only 1599cc

Into the 1980s and we’re talking turbocharging

The 1980s saw the introduction of turbocharging to the BD range with the 1778cc BDT motor implanted into the RWD, Ford Escort RS1700T. Problems with the RS1700T’s development and the introduction of 4WD into rallying meant the car was never raced, and the project was abandoned in favor of the RS200. But the DBT motor was retained, and once the RS200 hit the dirt and gravel tracks of early Group B rallying, the 1800cc BDT was chucking out a hearty 250bhp.

In 1983, Cosworth would release a BD motor for a road car for only the second time with 1601cc and 1701cc options for the Caterham Super Seven. That engine was given the designation BDR.

The abolition of Group B rallying saw the birth of Group B Rallycross, and the RS200’s BDT now became known as the BDT-E (Evolution). With fewer technical restrictions and Rallycross’s track-based safety regulations, the engine size swelled to 2100cc, boost pressures went up, and power spiked to over 600bhp.

A mind-blowing 12-year World Record

The 1986 BDT-E powered Ford RS200 Evolution, of which only 24 are reported to have been built, held the Guinness Book Of Records title for the World’s Fastest Accelerating Car for 12 years. A certain Stig Blomqvist rocketed the RS to 62mph in a blistering 3.07secs. That’s neck-snapping, even by today’s Supercar standards.

Cosworth would go on to produce engines for Ford in the Escort Cosworth and Sierra Cosworth – both based on the Ford Pinto, 1993cc YB block – as well as co-engineer the engine on Mercedes Benz’s 190E 2.3-16.

They would again build for Formula 1 in the 1980s with the turbo-charged V6 GBA. At maximum boost, the GBA would produce around 900bhp. Later in that same decade, with turbo-charging being phased out of F1, Cosworth produced the 2992cc V10, naturally aspirated motor that produced 730bhp at 16 500rpm. In the States, the Cosworth name was synonymous with the 1990s and early 2000s Indy and Champ Car series with the 2650cc, turbocharged V8, producing a push-to-pass maximum of around 800bhp.

Today, Cosworth describes itself as “a global technology leader in the automotive, aerospace and marine sectors.” They employ some of the engineering world’s brightest minds and busy themselves with projects way beyond the humble, racing car engine beginnings of founders Mike Costin and Keith Duckworth. But it is the pursuit of engineering excellence, birthed by those highly skilled and passionate gearheads, that has driven the company to where it is today. Let’s also be thankful that they didn’t opt for the second name choice, also a mash-up of the names, and call the company Ducktin.