Last year, Mattel offered the Cybertruck to the fans of toy cars. And today it became known that the manufacturer of diecast cars will launch a model of the Tesla Roadster next year. That Tesla symbolizes the transition to sustainable production that Matchbox, part of the American toy group Mattel, wants to make.

Also, more attention will also be paid to sustainability in the production and packaging of the toys. By the end of this decade, Mattel aims to fully switch to sustainable production.

What Motivated Mattel To Make Such A Switch?

"Since the inception of the modern-day die-cast car nearly 70 years ago, Matchbox has been using design and innovation to connect kids with the real world around them through play," notes Roberto Stanichi, responsible for Mattel's auto division. If that world changes, Matchbox must also change.

It is of course no coincidence that a model of a Tesla Roadster was chosen when this new strategy was launched. After all, the American car manufacturer Tesla is the symbol of the revolution that the car sector is currently experiencing.

Matchbox's sustainable collection will soon be supplemented with models from Nissan, BMW, and Toyota. In the landscape elements, the petrol stations will also be joined by electric charging stations. In this way, a greater awareness of the ecological impact of the car sector can be stimulated among the children.

Sustainable Materials Are The Main Objective

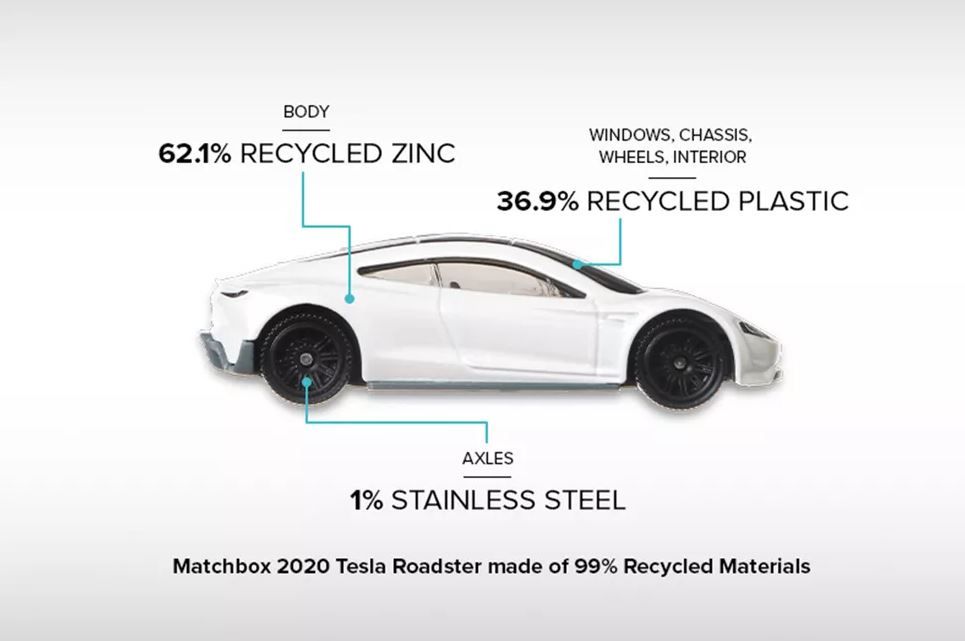

The operation is part of a broader sustainable shift that Matchbox aims to achieve. The new production will be made of 99 percent recycled material, which will include 62.1 percent zinc and 36.9 percent plastic. The remaining 1 percent consists of stainless steel.

In order to make its ecological footprint completely neutral, Matchbox also buys a package of emission rights. That money will be invested in the preservation of prairie landscapes in the American states of Colorado and Montana. Stanichi does argue that this process will take place in several phases. After all, the production systems must also be adapted to the new processes, without compromising quality.

Initially, a switch will be made to sustainable packaging. Only wood pulp and paper approved by the Forrest Stewardship Council will be used. A more environmentally friendly paint, which is based on water, will also be used.