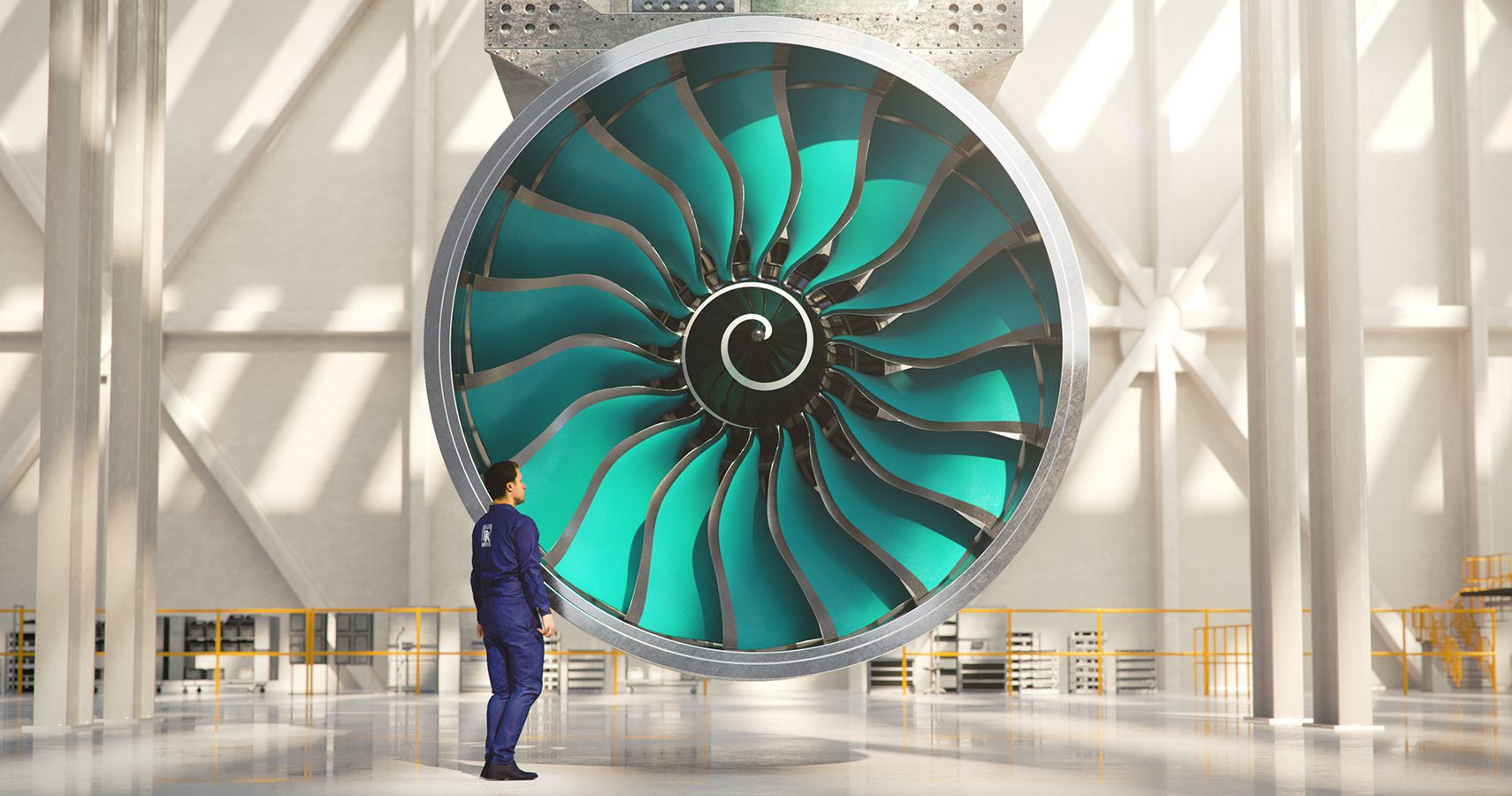

How large is an aero engine? At Rolls-Royce Holdings plc, it could measure up to 140 inches in diameter. Its quest to build the largest aero engine in the world—the UltraFan—has already commenced. It will not be just the world's biggest aircraft engine, but also serve as the basis for possibly a new family of engines seen to be powerful, yet efficient and sustainable.

More Efficient Engine Using Sustainable Aviation Fuel

Around 25% more fuel efficient than the first-generation Trent engine, Rolls-Royce's new UltraFan engines are expected to be the core of narrow-body and widebody planes. This improvement is seen as vital to achieving aviation sustainability since gas turbines are still expected to be mainstays of long-haul aviation for the next few years.

According to Rolls-Royce, the geared design of the UltraFan engine could help deliver a more efficient power for its high-thrust, high-bypass ratio. This level of efficiency could improve the economics of the aviation industry as it transitions to more sustainable fuels. Sustainable fuels are expected to generate greater costs in the short-term than traditional jet fuel. Its first test run will be done using 100% Sustainable Aviation Fuel.

Intelligent Engine With High-Tech Components

As part of Rolls-Royce’s IntelligentEngine vision, each fan blade of the UltraFan has a digital twin that could store real-life test data, which allows prediction of in-service performance. Data derived from tests at Rolls-Royce’s new £90-million Testbed 80 facility allows the company to better understand and improve its engines.

To deliver optimal fuel burn efficiency and low emissions, the UltraFan is based on a new, proven, Advance 3 core architecture and makes uses of ALECSys lean burn combustion system and carbon titanium fan blades. Its composite casing help cut weight by up to 1,500 lbs per aircraft. Furthermore, the UltraFan is designed to employ advanced ceramic matrix composite (CMC) components that could operate more effectively even in high-pressure turbine temperatures.

UltraFan Demonstrator Engine To Be Completed By End Of 2021

Rolls-Royce is currently working on the first module at its DemoWorks facility in Derby, United Kingdom. The company is also working on UltraFan’s carbon titanium fan system in Bristol, UK, as well as its 50MW Power Gearbox in Dahlewitz, Germany. The 140-inch diameter UltraFan demonstrator engine is expected to be completed by the end of 2021.

Source: Rolls-Royce Plc