Power, torque, and acceleration are all often associated with vehicle dynamics when discussing automobiles. However, even the most powerful piston engine will be rendered worthless if the driver lacks control over the vehicle. For this reason, car engineers began working on the suspension mechanism almost immediately after mastering the aforementioned dynamics.

Assisting in maximizing tire-to-road friction, providing steering steadiness, and ensuring passenger comfort are all responsibilities of the vehicle's suspension system.

The suspension would be unnecessary on a completely level road with no bumps or dips. Roads, on the other hand, are everything but. Even newly built roads contain tiny flaws that may affect a vehicle's wheels. It is these flaws that cause the wheels to be pushed about by the load exerted to them. In order to navigate without being troubled, you need a mechanism that will collect the force and enable the structure and body to travel without being disturbed as the tires follow irregularities on the route.

There are different types of suspensions at work depending on what kind of vehicle you use, SUV or supercar, but they generally have the same principles in their construction. Let's get more detailed on what are the components of a suspension system.

Different Types Of Suspension

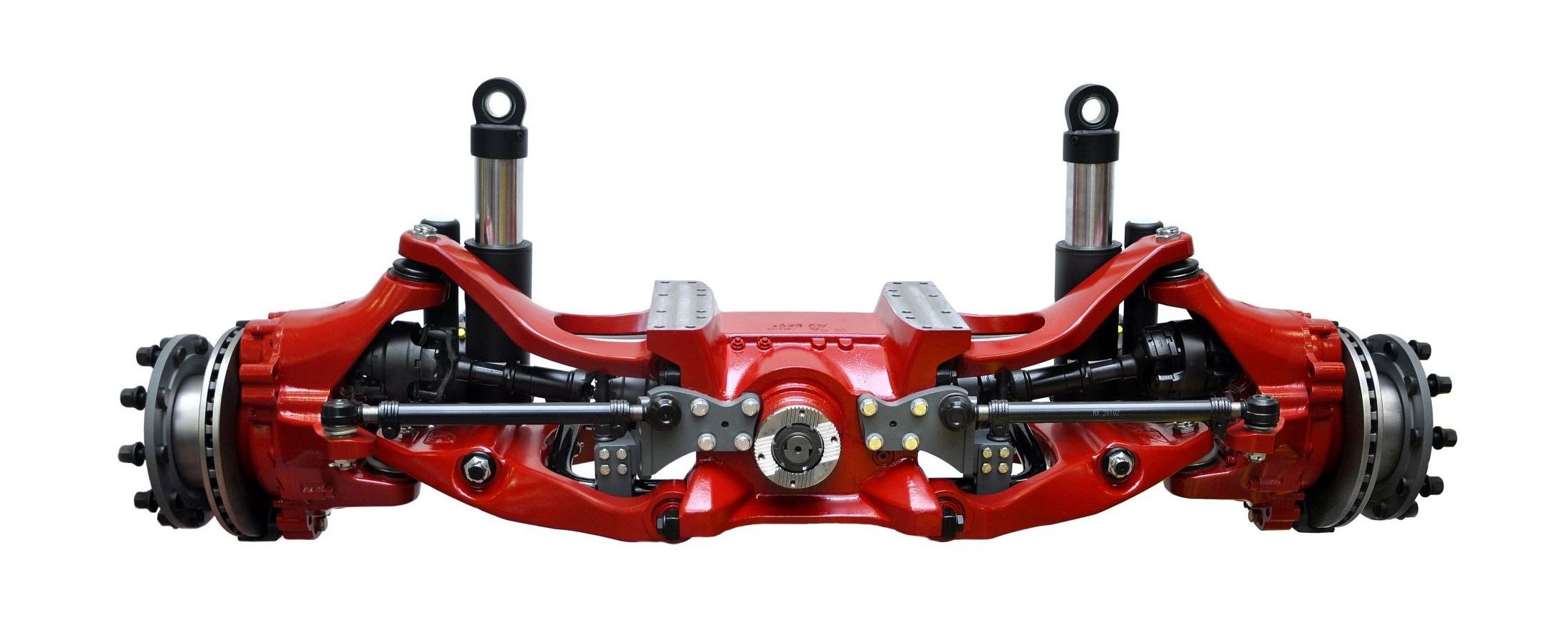

There are two main types of suspension systems: dependent and independent. These are technical words that describe the capacity of two wheels of a vehicle to operate independently of one another. A dependent suspension system often comprises a beam (a basic cart axle) or a live axle that maintains the wheels aligned to one another and perpendicular to the axle. It is important to note that as the camber of one wheel changes, the camber of the opposing wheel shifts in the same manner. This also includes De Dion suspensions, which bind the wheels together with a lot of sturdiness.

Independent suspension enables wheels to ascend and descend independently of one another without impacting the opposing wheel in the process. Independent suspensions also include those that use additional devices like sway bars to help connect the wheels.

The third sort of suspension is semi-dependent. Even though the movement of one wheel affects the movement of the other, the two aren't connected in a strict way. A good example of this kind of design is the twist-beam rear suspension.

Now let’s get to the components.

Springs, Tires, Shock Absorbers

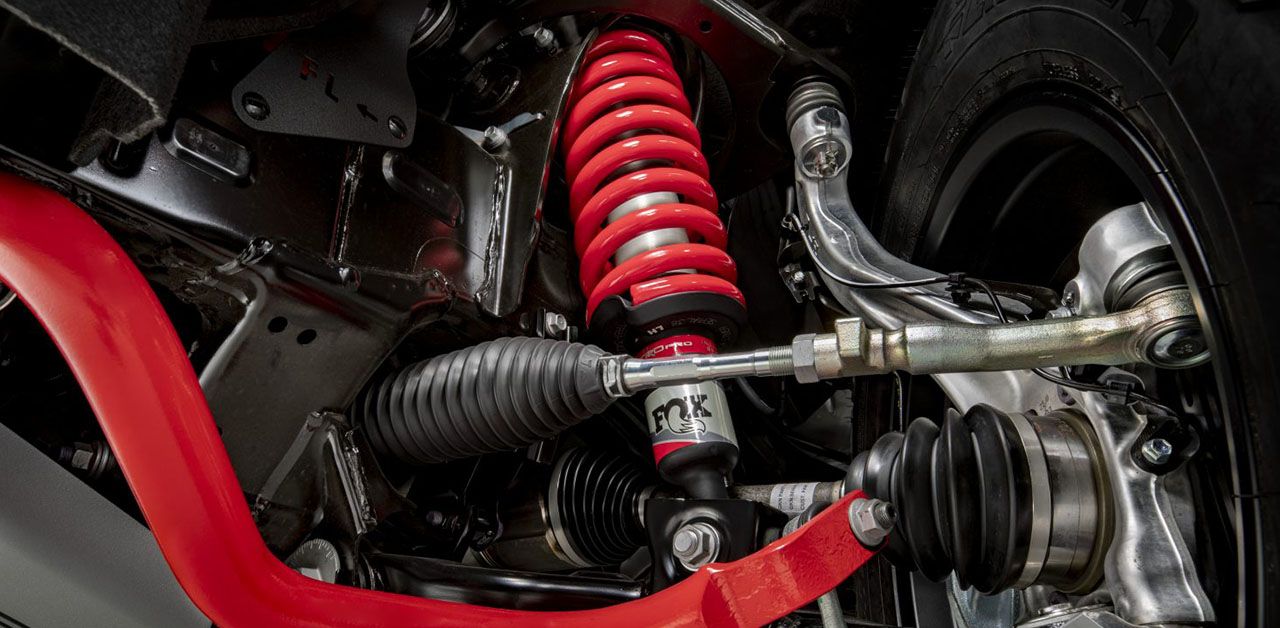

Suspension systems use coil springs to cushion the effect of bumps and potholes on the road. Metal rods are used in place of springs in certain model automobiles.

However, springs are often seen in automobiles, and they bend when they are hit. As a result, the occupants of the vehicle will be less affected by any force.

The wheels and tires are the elements of the suspension system that are visible externally. When a car is in motion, nothing except its tires contact the ground. This makes tires crucial.

A large portion of the force is transferred to the tires whenever you pass above a bump or hit a pothole. Additionally, braking and accelerating motions have a significant influence on the performance of the tires. Leaking or inadequate tread on your tires may cause you to lose control and swerve and mess up the smoothness of the ride.

Shock absorbers function in conjunction with your springs to minimize the effect of road imperfections like bumps and potholes. Despite the fact that the springs are theoretically responsible for absorbing the impact, it is the shock absorbers that provide assistance to the springs by limiting their mobility.

As a result, when you drive over a bump, your car won't bounce about like crazy. Thick oil is found within shock absorbers. If any of it were to escape, it might have an adverse effect on the suspension system as a whole.

Linkages, Joints & Bearings

Suspension system parts are linked together by a number of rods. It's a set of metal linkages that are very sturdy and should endure for the whole life of the automobile.

Getting into a collision and suffering damage to your rod are the only actual scenarios in which it may fail.

These elements are responsible for maintaining the connection between the linkages and the larger components. On top of that, by using components such as bearings and bushings, some elements may perform slide and twist operations as well. Also, lubrication is seldom required.

Despite this, rubber-based suspension bushings are prone to premature failure because of excessive use. It's possible that as time passes, the joints may become overly loose. As a result, if you ever experience a malfunction with your suspension system, it is most likely due to one of the minor joints, bearings, or bushings.

Steering System & Frame

Although the steering system is not a part of the suspension system, it works in harmony to turn the wheels. The steering system has some influence on several other parts of the car, such as the links, tie rods, joints, wheels, and so on.

Your vehicle's wheels rotate in unison with your rotational motions as you spin the steering wheel.

The frame is probably the most crucial part of the suspension system. It is, in essence, the structural backbone that supports the mass and load of the whole vehicle, including all of its individual elements.

Although it assists in maintaining the car's bodywork and engine, other sections of the suspension system aid in this support too.