While Formula 1, drifting, and rally-cross has grown more popular in recent years, NASCAR still reigns supreme in the land of the free. Stock-car racing has gone through some radical changes since the early days in the late 1940s. In 1947, the National Association for Stock Car Auto Racing (NASCAR) was formed to create standards and rules for stock-car racing, as well as a system for selecting a national champion based on performance at races across the country. The early races were held on dirt tracks that quickly developed bumps and ruts during the race. The unmodified stock cars were not built for that type of abuse, so NASCAR decided to allow modifications that improved durability.

Updated January 2022: If you're a NASCAR fan who's wondering how the cars are actually constructed and how much they actually have in common with the road cars they're "based on", you'll be happy to know that we've updated this article with even more information about NASCAR that every gearhead with an interest in racing should know.

With every passing year, more modifications were permitted, often to improve performance but also to increase safety, as there's been some horrible crashes over the years. NASCAR strictly controls all vehicle modifications. The NASCAR rule book specifies all guidelines in detail and the cars are checked for compliance at every race. NASCAR has reached the point where the race cars have very little in common with street cars. In fact, some would claim NASCAR doesn't really make sense anymore. Almost every detail of a NASCAR car is handmade. Although the race cars display the brand names Ford, Chevrolet, Dodge, and Toyota, none of them originated from an assembly line in Detroit or Japan. While these car companies get some credit for racing successes and make significant financial and technical contributions, none of the parts come from their factories. Here are 25 things gearheads should know about NASCAR race cars.

25 It All Starts With A Frame

The frame (chassis) consists of a structure of square and round steel tubing of variable thickness. The roll cage makes up most of the structure. Surrounding the driver, it is designed to stay together in the event of a crash. Before the body, engine or any other parts can be added to the chassis, it must go through a detailed pre-certified inspection process at the NASCAR Research and Development Center.

The X-Y-Z coordinates of the chassis are measured using a CMM ROMER arm. The measurements must meet strict standards with small tolerances. An ultrasonic meter is used to measure thickness. The chassis must pass nearly 50 ROMER measurements and over 150 material thickness measurements to be pre-certified.

24 The Roll Cage

The design of a NASCAR race car is driven by two factors: performance and safety. The ideal vehicle delivers the performance needed to win races while protecting the driver in the event of a crash. The essential element for surviving an accident is removing kinetic energy from the driver's body slowly. The street car’s structure is designed to crush and thus, absorb energy, allowing the safety devices, like airbags and seat belts, the time to slow the driver's body down.

The front and rear clips of a race car, built from thinner steel tubing, are designed crush when the car hits a wall or another vehicle. The roll cage (middle section) is built stronger, to maintain its integrity during a crash and protect the driver.

23 Traditional NASCAR Body

Making the body of a NASCAR race car is a labor-intensive process because most of the panels are formed by trimming and then hand-rolling flat sheet metal between rollers. The metal is slowly bent and curved until the contour matches the templates and fits on the car.

The shape must adhere to strict NASCAR regulations, which are represented by a set of 30 templates, each shaped to fit a different contour of the car. When a template is applied, the gap between the template and the vehicle cannot exceed the specified tolerance. These tolerances vary depending upon location, between 0.07 inches (0.18 cm) and 0.5 inches (1.27 cm).

22 NASCAR Flange-fit Composite Body

These days, NASCAR is successfully phasing out the traditional sheet metal body in favor of the new flange-fit composite material for the Xfinity Series. The governing body is considering a similar path for the Monster Energy Cup Series, as well.

The new non-metal bodies feature thirteen separate panels attached by flanges that can be replaced in sections when required. Since the panels are not welded to the frame, they are lighter, less prone to deformities on impact, and easier to repair when damaged. NASCAR claims race teams are spending less time repairing their cars, more time on the track, and less money during the season.

21 Windshield Made Of Lexan

The phrase written on the top of Kevin Harvick’s car, “If you let me pass, we all get bloomin’ onions” is probably not enough to convince any competitors to move over but it's certainly good for a laugh.

The text is written on a windshield made of Lexan, which is the same polycarbonate material used for fighter-plane canopies. The material is durable but soft, meaning it doesn’t shatter when hit by an object. Instead, the object dents, scratches, or embeds itself in the windshield. To prevent scratches and damage to the Lexan, NASCAR teams place a durable adhesive film over the windshields that is as clear as glass. After each race, the film is peeled off and replaced.

20 Headlight And Taillight Decals

NASCAR race cars have no functioning headlights or taillights and use decals instead, for several reasons. Although they are almost entirely hand-made, the cars are still required to look like production vehicles. No operating headlights or taillights are needed because the cars don’t race at night.

However, safety is, perhaps, the most important reason they are excluded. NASCAR race cars frequently bump into each other during a race. With no light lenses to break during collisions, there is no glass on the track to puncture other car’s tires. Furthermore, decals weigh much less than headlights and the various wiring necessary to power them.

19 Safety Feature: Roof Flaps

A race car's body is aerodynamically designed to optimize downforce, increasing the vertical force on the tires, thus creating more traction through corners. However, if a race car is spun so air is flowing in reverse, the design causes lift, instead.

If the speed of the car is high enough—more than 195 mph and the car has rotated about 140 degrees—enough lift will be generated to pick up the car. To prevent this, NASCAR officials developed a set of flaps that are recessed into pockets on the roof of the vehicle. The resultant change in aerodynamics keeps the cars from going airborne and tumbling over the track.

18 Short-track Cars

Short tracks are less than one mile in length and the cars require a different design than super-speedway cars. The ideal car design will have the maximum downforce possible, permitting it to go around the tighter turns as quickly as possible. Although there is a trade-off between downforce and drag on the short track cars, reducing drag is not critical because the engine power is not restricted and the speeds are generally lower.

Extensive wind tunnel testing has shown that mounting the car body as far back on the frame as possible (about five inches further back compared to the body location on a superspeedway car) helps the car create extra downforce. Short-track cars have more pronounced and curved front fenders, which also help to produce downforce.

17 Superspeedway Cars

Superspeedway tracks are much longer and straighter than short tracks and they feature high banks, allowing cars to maintain a high speed all the way around the track. These tracks require race teams to use engine restrictor plates that reduce engine power from about 750 horsepower to 450. At Daytona and Talladega, NASCAR now requires the use a thick tapered spacer with holes designed to restrict air flow.

With reduced power, the goal of designing a car for the super-speedway tracks is to minimize drag. Less drag is partially achieved by mounting the body forward on the frame. The fenders and sides are less contoured and the smaller-sized openings will deliver the necessary cooling airflow creates the least amount of drag.

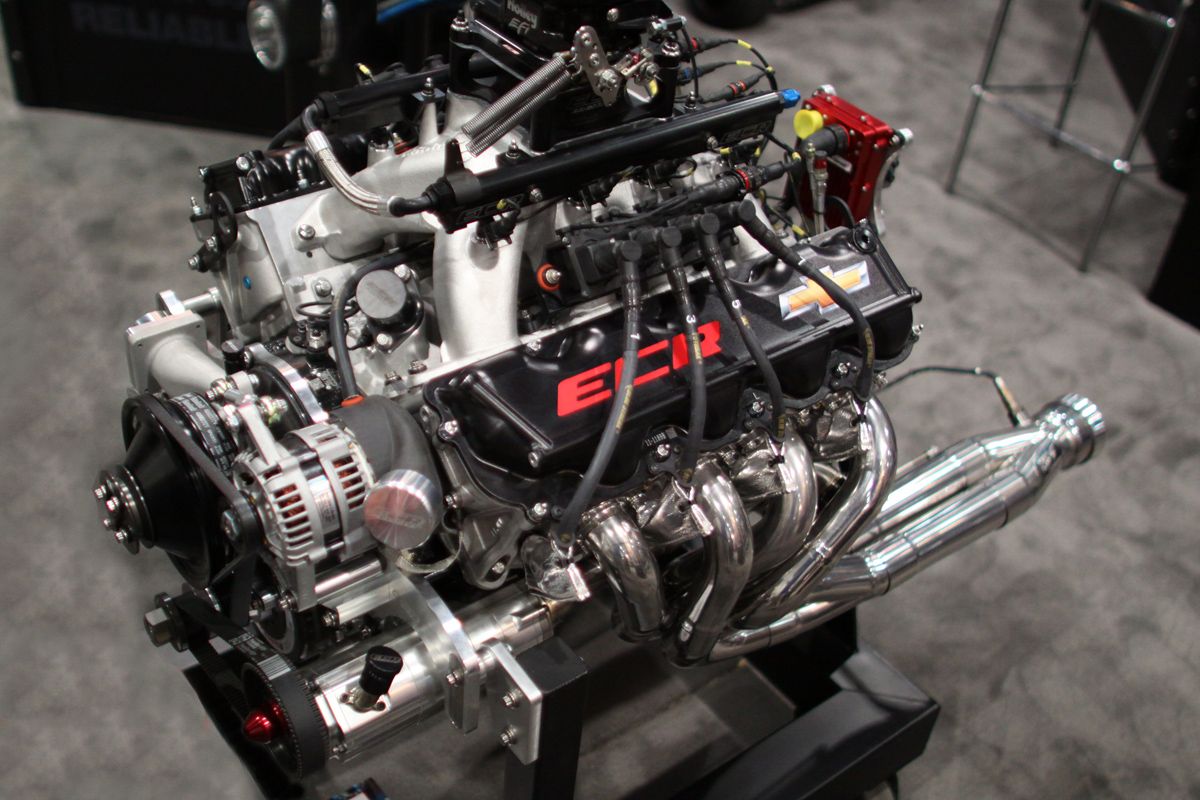

16 The Engine Block

While every component of a NASCAR race car is essential to its performance, the engine may be the most critical element. To be successful, it must generate an enormous amount of power for several continuous hours without failing. NASCAR engines share some features with street-car engines. For example, Dodge provides Bill Davis Racing with engines and cylinder heads based on a 340-cubic-inch V8 design that was produced in the 1960s.

The engine blocks and heads are custom-made for racing but they have the same cylinder bore centerlines. They start at the same size but get bigger during the building process and like the original engines from the 1960s, the valves are driven by pushrods.

15 Engines Produce Up To 750 Hp Without Forced Induction

The engines in today's NASCAR race cars produce around 750 (and sometimes, more than 800) horsepower. All that power is generated without turbochargers or superchargers. With a displacement of 358 cubic inches, they have extremely radical cam profiles, opening the intake valves much earlier and keeping them open longer than in street-car engines. More air packed into the cylinders means more power.

The exhaust system has no mufflers or catalytic converters, providing very little engine back pressure. The programmable, high-intensity ignition systems permit customized, optimum spark timing for maximum power. All subsystems, like alternators, steering pumps, coolant pumps, and oil pumps are designed to run at sustained high speeds and temperatures.

14 Engine Liquids

A racing engine that runs at high temperatures uses three times as much motor oil (about 13 quarts) as a street car, typically a synthetic oil. Many race teams use Pennzoil and the company claims their Platinum: Full Synthetic Motor Oil with PurePlus Technology is created using a “gas-to-liquid process which converts natural gas into a…high quality full synthetic base oil. Because our base oil is made from natural gas, it is clear with fewer of the impurities found in crude oil, the start for many other traditional and synthetic motor oils. To that pure, clear base we add our high-performance additives to create…a full synthetic oil designed for complete engine protection, without compromise.”

13 Fuel Tanks Built For Safety

Like many other components, NASCAR race cars in the 1950s used the same fuel tanks found in the street cars they were based on. Reinforcements were primitive, sometimes using wood to secure the tank. As a result, leaks and combustion were common. The fuel tanks (also called cells) in modern-day race cars have a 22-gallon capacity and several built-in safety features to limit rupture or ignition.

Built with a steel outer layer and a hard, plastic inner layer, the fuel cell is mounted in the rear of the car and held securely in place by four braces that prevent it from flying loose during a collision. Inside, the cell is filled with foam, which minimizes the amount of air and keeps the fuel from sloshing about while reducing potential dangers.

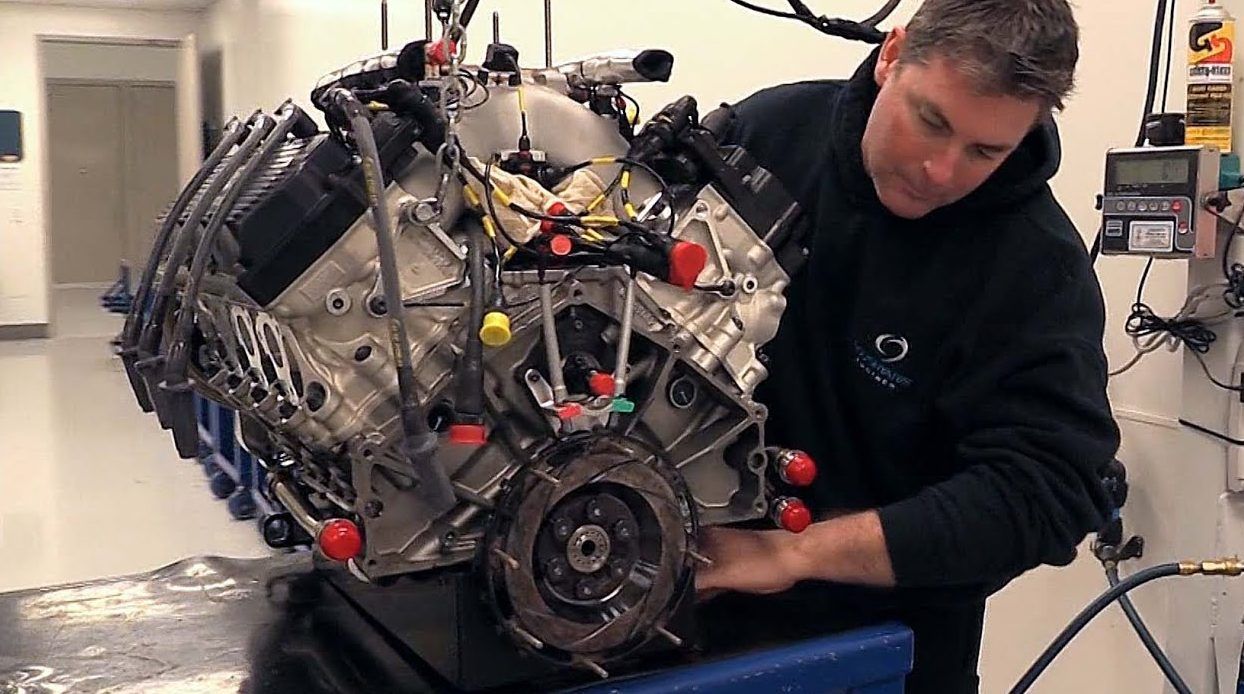

12 Engine Testing

Almost any engine problem during a NASCAR race eliminates the chance of winning. Therefore, ensuring the reliability of the engine by extensive testing and inspection is critical. After assembly, the engine is broken-in by running it on a dynamometer (which measures engine power output) for 30 minutes. An inspection follows and the filters are checked for excess metal shavings that would indicate abnormal wear. Back on the dynamometer for two hours, the ignition timing is fine-tuned for maximizing power and the engine is cycled through several power and speed ranges.

The valve train is pulled to inspect the valve lifters and camshaft. The cylinders are examined for abnormal wear and then pressurized to measure the leakdown rate, indicating the capacity to hold pressure. Once all tests and inspections are completed, the engine is ready to race.

11 Rebuild The Engine After Every Race

Most production car engines are designed to last over 100,000 miles. NASCAR race car engines are designed to last one race (500 miles, in the case of the Daytona 500). While the same version of an engine is typically used for an entire season, it is rebuilt after each race.

However, starting in 2018, NASCAR Cup teams were required to run engines multiple races. Thirteen short-block engines (engine block, connecting rods and pistons, camshaft, and crankshaft) must be used for two full race weekends. To prevent tampering, the engines are sealed between the points races. NASCAR has implemented other new regulations for backup engines installed in either a primary vehicle or a backup vehicle.

10 How Many Gears?

Anyone who drives a car with a manual transmission knows how to depress the clutch before shifting and release it to engage the new gear. However, gears on a car with a manual transmission can be changed without using the clutch. The change requires the engine RPM, the speed of the vehicle, and the gear ratios to be just right. The synchros in the transmission allow the two gears to match rotational speeds as they come in contact.

A NASCAR race car has a four-speed manual transmission but the gears do not use synchros. To change gears without the clutch, drivers must have a remarkable feel for the car and understand at what road speed the gear-change should be made.

9 Inner And Outer Tires

NASCAR requires that tires contain an inner liner, which is basically a second tire installed inside the first tire. It has its own air supply, so if the outer tire deflates, the inner tire remains intact, permitting the driver to bring the car to a controlled stop.

When tires heat up, moisture inside vaporizes and expands, causing the pressure to increase. Even minor changes in tire pressure can significantly affect the car’s handling. Compressed nitrogen holds a smaller amount of moisture than compressed air, so many racing teams use nitrogen instead of air in the tires. The race teams have more control over pressure increases when the tires heat up.

8 Body Paint Or Wrap?

At the NASCAR Technical Institute garage, a long piece of 3M vinyl is pulled from its package and carefully stretched over the right side of the car. Next, a squeegee device is applied, pushing out air bubbles until the vinyl is as smooth and seamless as an expensive paint job. When it is completed, the entire car is covered in vinyl bedecked with all the graphic designs the car owner and sponsor requested.

Every week, nearly half of the primary cars in a NASCAR Cup event are wrapped. More than half of the backup cars are also wrapped, allowing the teams to use the same car the following week and change sponsors without repainting. The speed and flexibility of the wrapping process help owners to keep inventory down.

7 Tire Compounds And Treadless Design

While a tread pattern on a tire helps in wet weather, in dry weather, better traction is achieved with the whole tire touching the ground. Race cars use tires without tread to achieve maximum rubber contact with a dry track. NASCAR races stop whenever the track is wet. The performance of tires is not only determined by how much rubber touches the track but also the compounds used in their production.

A softer compound provides better grip but wears faster and a harder compound lasts longer. Tire wear is determined by track surface, type of banking, number of turns, and tightness of turns. Goodyear and NASCAR have discovered the best compounds for the outside and inside tires for each track and the race teams are required to use these.

6 Pit Stop Tire Change Trick

All race car enthusiasts know that pit stop time can make the difference between first and last place. A typical NASCAR pit stop lasts from 12 to 14 seconds while seven people completely refuel the car and change all four tires. But how does the crew get the tires on and off so fast?

Although it requires remarkable hand-eye coordination, the teams use a couple of tricks to make the process a bit easier. When the replacement tire is mounted on the car, the lug nuts are already attached to the wheel. The long studs have no threads for the first three-quarters of an inch, ensuring that the lug nuts do not get cross-threaded and making it easier for the tire to be positioned.