Carbon fiber was invented around 1879 after Thomas Edison baked cotton threads or bamboo silvers at high temperatures. The resulting carbonization created an all-carbon-fiber filament. A more modern version was invented in refined in Cleveland, OH in 1958. This fiber contained around 20% carbon and had low strength and stiffness properties, but it's not practical to have it widely used. It's a very expensive material to produce, as both the ingredients and the process are very costly and time-consuming, as it is part chemical and part mechanical. The process also creates a cloud of dust that can be a health hazard when released, and it's not very eco-friendly because it produces a lot of waste once disposed of.

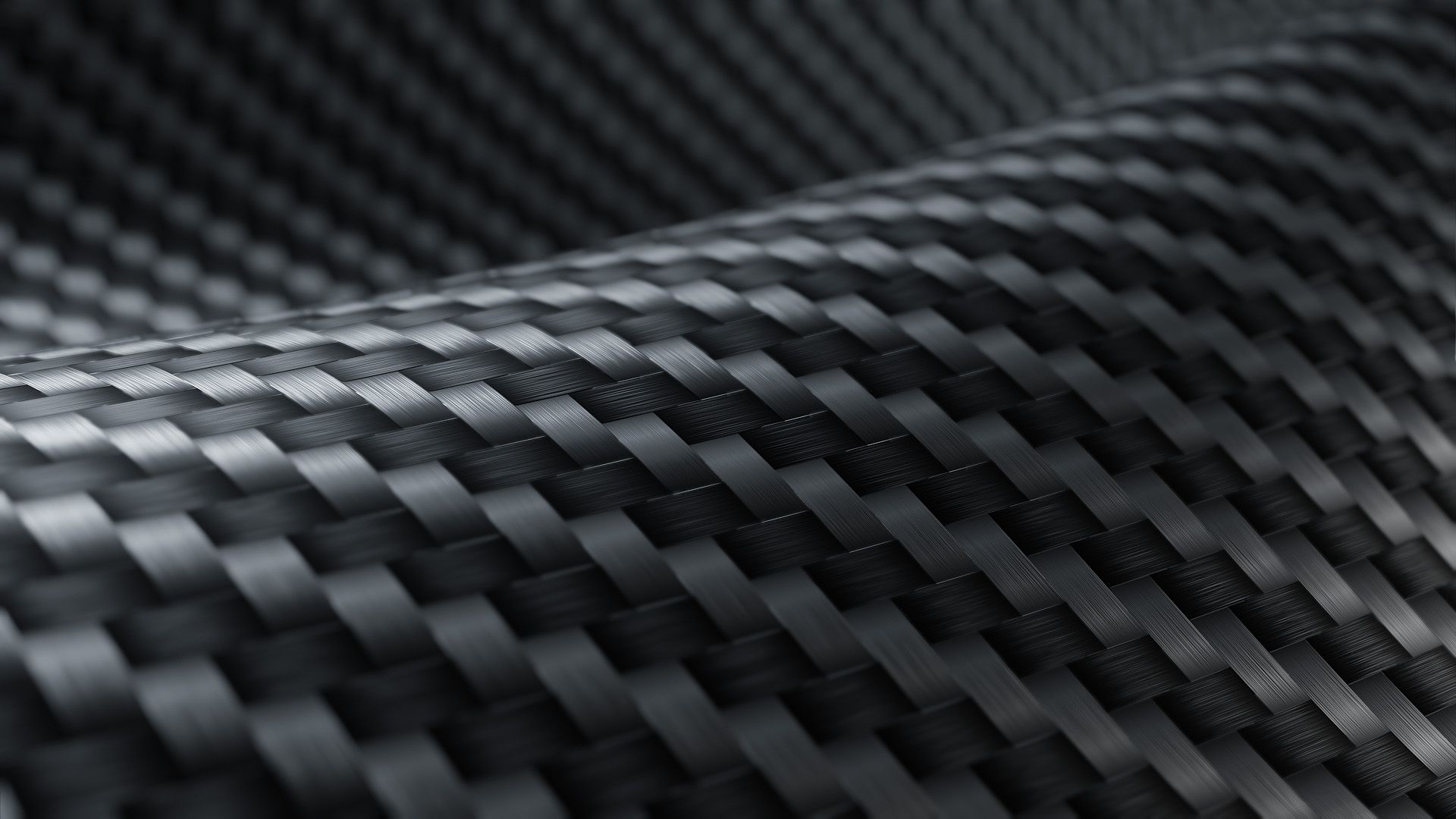

However, despite the rarity of carbon fiber, it has several advantages, such as high stiffness, high tensile strength, low weight, high chemical resistance, high-temperature tolerance, and low thermal expansion.

Read on to find out why, despite all these benefits, carbon fiber just isn't that available.

Price Is A Significant Deterrent

For all its advantages and for its simple appearance, carbon fiber is not a cheap material to produce. It has the potential to compete with fiberglass, and it had a lot of potential upon its unveiling in the 1960s. While it's still available today, the price makes it a little harder to come by.

The procedure and the materials involved are the reason for its inflated price tag. Carbon fiber is usually not cheaper than $10 per pound, and it's not used for wide-scale deployment. The manufacturing procedure takes a lot of energy and specialized equipment, and that kind of procedure is hardly simple, resulting in a price increase.

Health Hazards Are A Risk

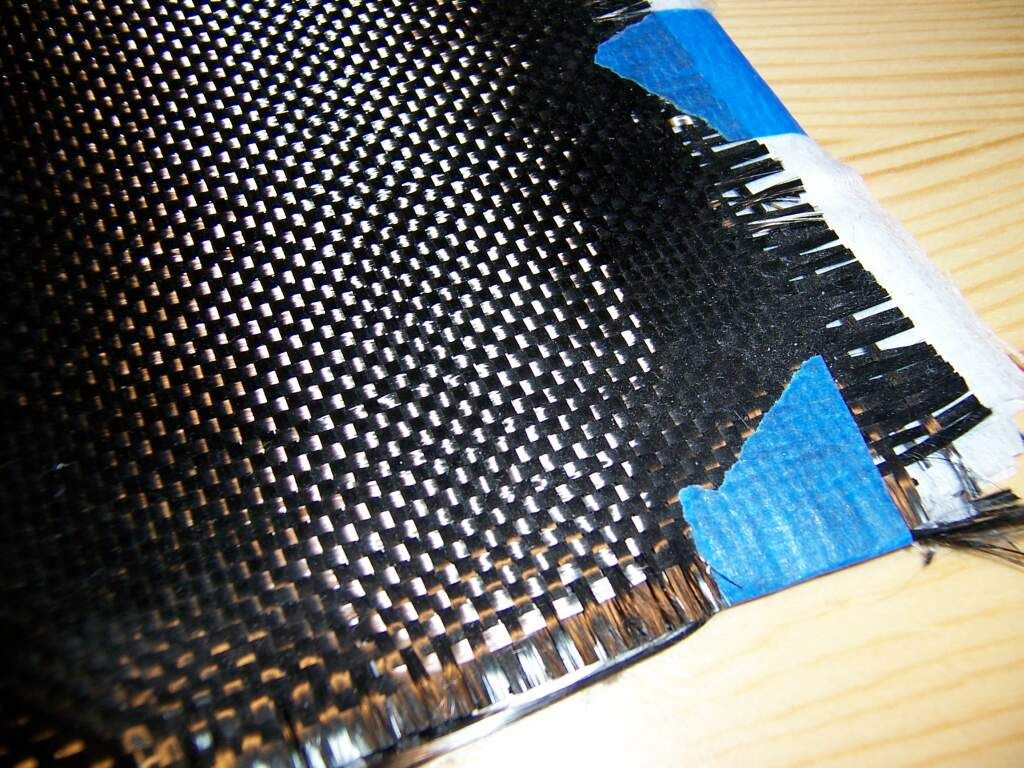

Mechanical irritation and abrasion similar to that of glass fibers can cause many health hazards. Given that carbon fibers are easily broken by stretching, the fibers transform into fine dust during cutting, and this can cause breathing and respiratory problems when released into the air.

Further, these fibers, if left uncontrolled, could possibly stick into human skin or the mucous membranes, causing irritation. They also have a coating capable of causing chemical irritation. Solvents used in creating carbon fiber are volatile, flammable, and irritating to skin and eyes. Health hazards include blurry vision, upper respiratory tract issues, dizziness, drowsiness, nausea, and vomiting.

It's Hardly Eco-Friendly

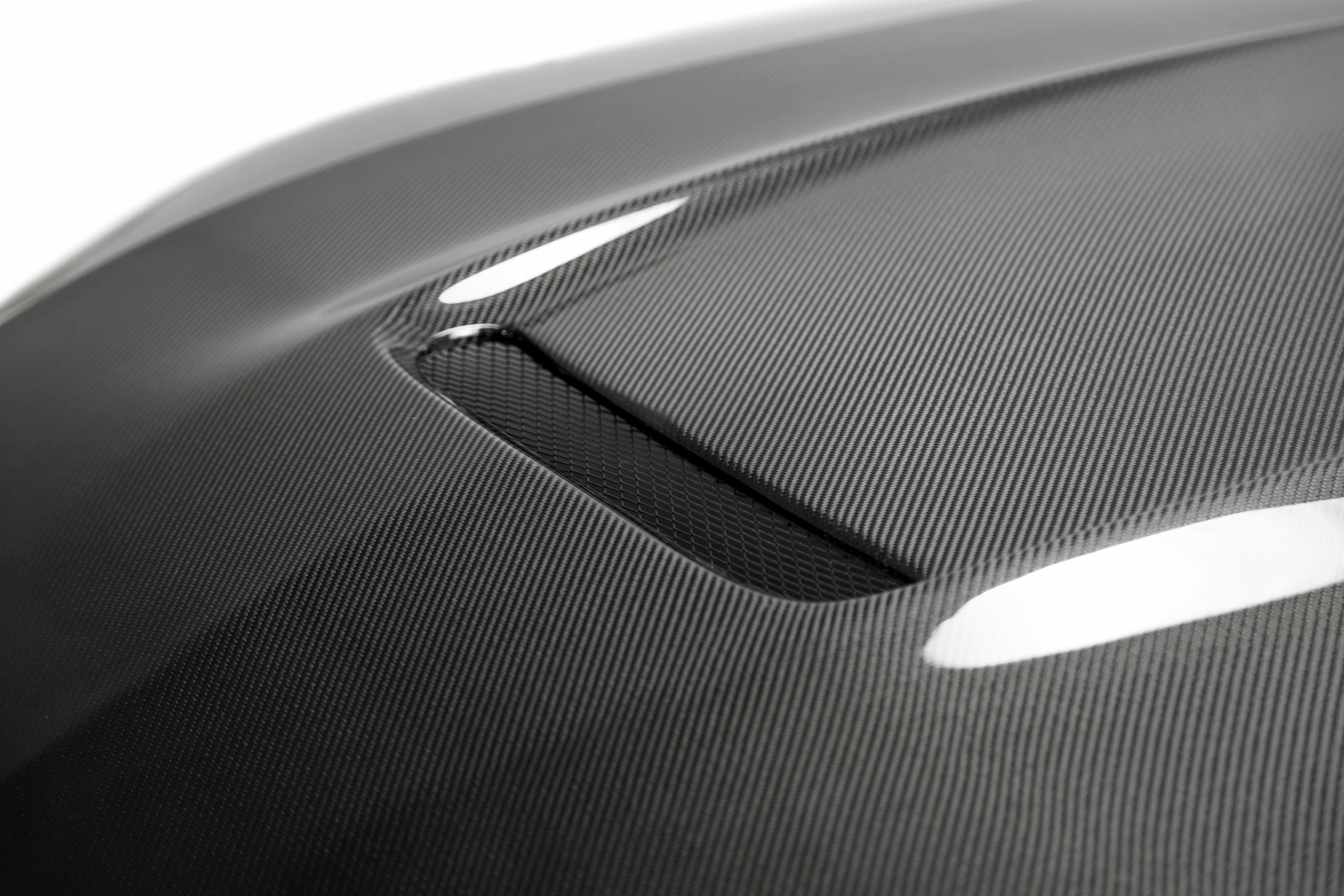

Carbon Fiber is also not an eco-friendly structure, as it produces a lot of waste and has not been able to be efficiently recycled yet. It's also irreparable if a carbon structure is dint or cracked, as it lacks the pliability of a steel structure. Damages mean fibers are broken and strength is compromised, resulting in structures needing to be removed and replaced. At the moment, there is no easy way of recycling carbon fiber.

There's An Elaborate Routine For Processing

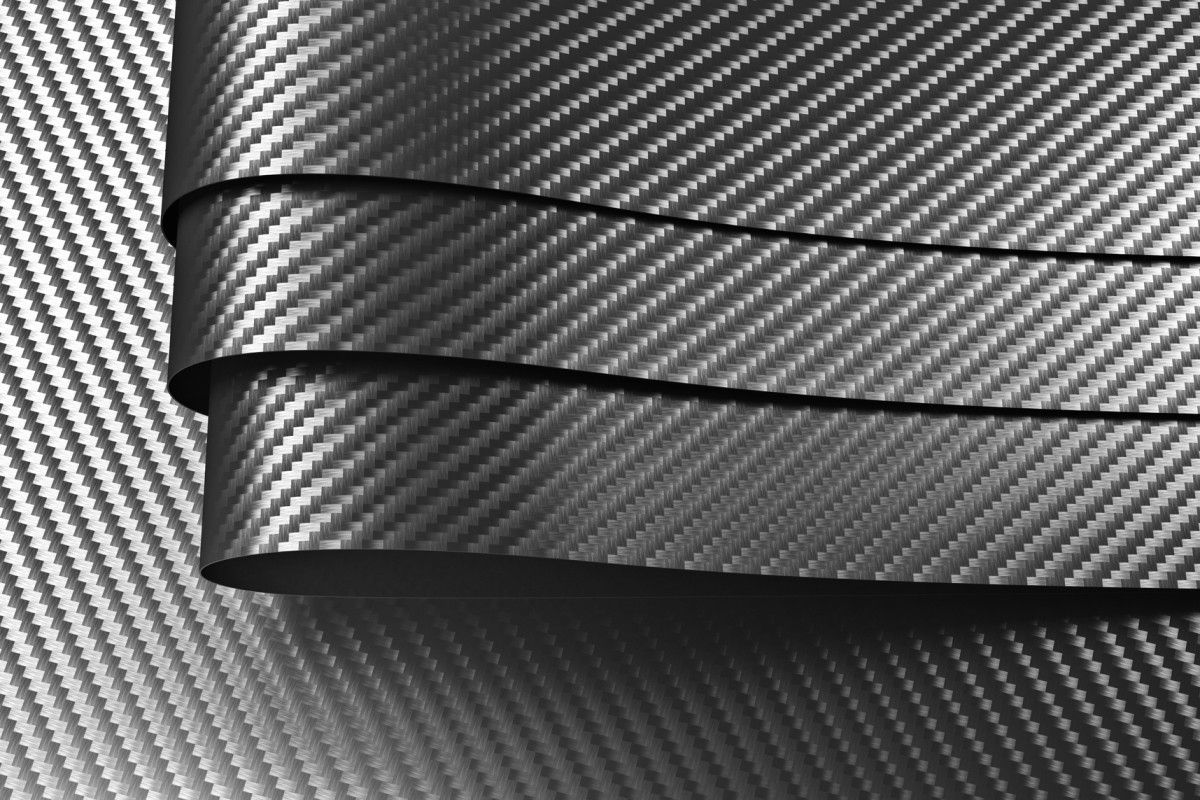

The manufacturing process of carbon fiber is particular, involved, detailed, and elaborate. During the manufacturing procedure, a base such as an organic polymer is involved, and carbon atoms bind together long strings of molecules called polyacrylonitrile, which is a material similar to acrylics in carpets and sweaters.

However, in order to make the material both stronger and lighter than steel, the process removes half of the starting material's acrylic, accounting for the “carbon” in carbon fiber. This process takes a lot of energy and specialized equipment.

A lot of heat needs to be present for a lot of these modifications to occur. Carbonization requires so much heat around 1000 degrees Celsius that the power bill alone is a liability during production.

Sources: gizmodo.com, innovativecomposite.com, monash.edu,