The Torsen Differential is one of many possible differentials that cars use. This one is known for sensing torque and distributing it proportionally to the tires with better traction. This differential combines other types of differentials and improves on them to achieve specific outcomes. It has many practical applications with car racing, though not with drag racing, and three main versions have existed since this differential was developed. It can be better or worse than other differentials, depending on what the driver is seeking, but it has more applications and versatility thanks to its complex nature.

Read on to discover more about the features, aspects, benefits, and drawbacks of the Torsen Differential.

What Is It?

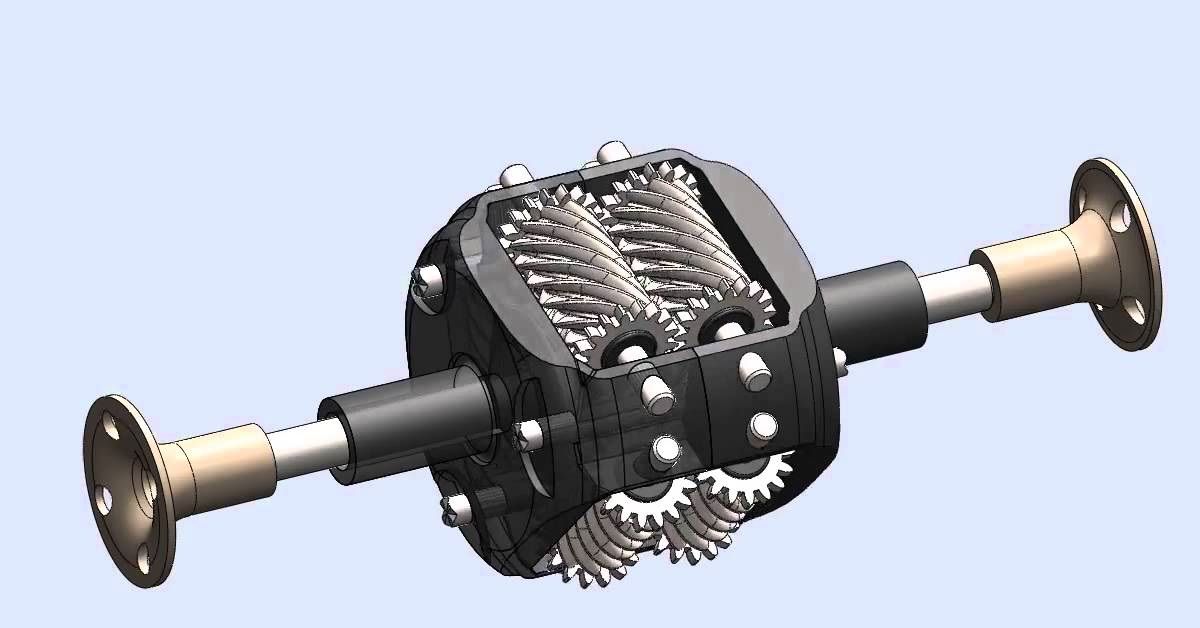

The name 'Torsen Differential' is derived from the term “Torque-Sensing.” This differential has an ability to be torque-biasing, meaning that the torque is distributed among all four tires according to where it is most required at a given moment.

Friction is properly managed because it results from proper torque application to the helical gearing. Torque is then applied to the differential casing once it is properly applied to the gearing, allowing the Torsen differentials to prevent wheel spin and bias torque.

Further, the Torsen differentials, being torque-biasing, have the advantage of operating without losing traction in the process. The Torsen differential supports imbalances in traction because the friction it manages from the helical gearing is tuned and managed across a performance range. The result? Tires with better traction receive more torque, while tires with worse traction receive less torque.

Friction is proportional to the load the vehicle carries, and this ability is known as Torque Bias Ratio (TBR), a high traction-low traction ratio while the differential is locked, where imbalances in friction receive the support they need. Higher TBR numbers equal more aggressive traction performance.

Torsen differentials can also support traction imbalance under heavy throttle thanks to input torque being applied to a helical gear. The result is thrust forces then push the gear into the differential casing, and that contact generates friction while still differentiating freely and smoothly when torque levels are lower.

Different Kinds of Differentials

The Torsen Differential is one of many various differentials that exist as alternatives.

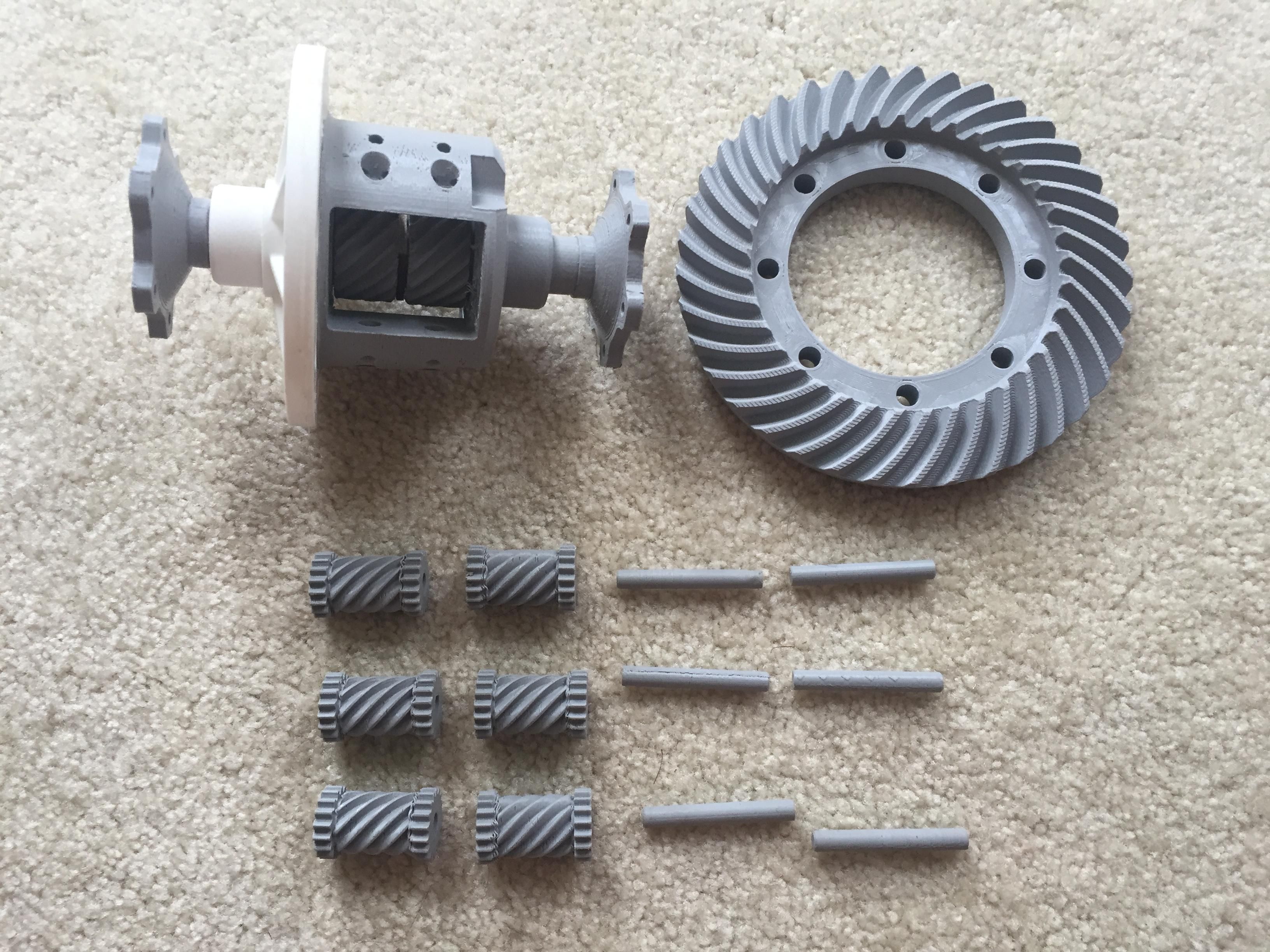

The most basic is the open differential, which comprises two halves of an axle with a gear on each end while a third gear connects the aforementioned two. The result is three sides of a square, known as the core mechanism, necessitating a fourth gear to complete the square and give some extra strength to the differential as a whole. Ring gears are then added to the differential case that houses these gears, sending power to the wheels after using a pinion to connect to the drive shaft. Its benefits are derived from its simplicity, as there are fewer variables on which to focus. Usually, the main focus goes to making the axle more effective at cornering by the outside wheel of a turn to move faster than the inside wheel does. However, while an open differential is more inexpensive to manufacture, it suffers drawbacks from evenly-split torque between both wheels. Power is limited in its transmission.

Another type is the locked differential, mainly for off-roading vehicles. It's a variant on the open differential in that it can be locked in place to create a fixed axle instead of an independent one via a manual or electronic setting. In this variant, torque isn't evenly split, so more torque can be channeled to a wheel with better traction, just like the Torsen differential does. Torque does not suffer on account of the wheel with lower traction, which comes in useful when driving over rougher terrain at high speeds. Sadly, locked differentials have their disadvantages, especially with binding, a scenario where excess (torque) accumulates within the drivetrain seeking release, and the wheels have to leave the ground to reset position or the locks have to be released. The latter is simpler.

A welded/spool differential is a variant on the locked (and subvariant of the open) in that it has been permanently welded from an open differential into a fixed axle. Because of the permanence factor, this rarely occurs. It's mainly about keeping both wheels spinning simultaneously, like in drift cars. It's not recommended for regular vehicles.

Limited Slip Differentials combine open and locked differentials via an elaborate system involving a mechanical clutch that surrounds the open differential's core gearing with two force-exerting pressure rings pushing on two sets of clutch plates near the gears. It can also be a one-way system where the pressure is only exerted under acceleration or a two-way system with pressure also exerted under deceleration.

Another type of limited slip differential is viscous, meaning it uses a thick liquid instead of clutches for generating differential-altering resistance. These have fewer moving parts than the mechanical version, but they come with their own set of complications.

Good For Road Racing But Not Drag Racing

Torsen Differentials, while not ideal for drag racing, are practical for road racing. These differentials complement a well-balanced suspension package, resulting in ideal traction for a vehicle. Of note is that the Torsen Differential can sense torque, which allows engine power to stay grounded.

As mentioned before, this differential's ability to distribute torque to tires with superior traction is a significant factor in racing. The Torsen Differential often operates like the aforementioned open differential while there is equal torque transmitted to each rear wheel.

However, clutch plates eventually wear out and require replacement, though the subsequent axle endplay doesn't occur with Torsen Differentials like it would with other differentials. So fixed-mount brake calipers work well with Torsen Differentials. All this said, drag strip racing does not go well with the features and functions of the Torsen Differential.

Torsen Variants

Three different Torsen variants exist, pulled from various points in its evolution. There's the T-1, the T-2, and the T-3. The T-1 increases internal friction via crossed axis helical gears, resulting in higher torque bias ratios, though not without higher backlash, as well as more possible noise, vibration, and harshness, problems. With the T-1, precise installation is key. The later T-2 accomplishes the same effect via parallel gear arrangement. T-3 is the most modern version. Torque is not split evenly, because as a planetary type differential, the front and center differentials are located within the same unit.

Sources: torsen.com, matfoundrygroup.com, maximummotorsports.com, awdwiki.com,